Tapping noise after rebuild on 4AGE small port

Tapping noise after rebuild on 4AGE small port

Hi,

I'm new to the forum but need some help! This is my first attempt at a rebuild after I had a bottom end failure on a track day at Donington. I've rebuilt it, it seems to be running okay apart from this annoying tapping noise. Above 3000rpm it gets quite loud, and then is particularly loud on overrun. I've checked all the valve clearances and they are fine. I think the timing is okay, the compression is okay and it seems to run okay. There's a high probably that I've put some of the valve springs in upside down as I didn't realise there was a right way up.

The engine is a small port 4AGE out of a toyota corolla.

Has anyone got any ideas?

Here's a vid of the noise:

https://www.youtube.com/watch?v=UYv0qfhJ1Ho

I'm new to the forum but need some help! This is my first attempt at a rebuild after I had a bottom end failure on a track day at Donington. I've rebuilt it, it seems to be running okay apart from this annoying tapping noise. Above 3000rpm it gets quite loud, and then is particularly loud on overrun. I've checked all the valve clearances and they are fine. I think the timing is okay, the compression is okay and it seems to run okay. There's a high probably that I've put some of the valve springs in upside down as I didn't realise there was a right way up.

The engine is a small port 4AGE out of a toyota corolla.

Has anyone got any ideas?

Here's a vid of the noise:

https://www.youtube.com/watch?v=UYv0qfhJ1Ho

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: Tapping noise after rebuild on 4AGE small port

I don't diagnose sounds unless I am there. Too much is lost in a video or sound clip for me to feel like there is any value in doing so.

Start by getting yourself a stethoscope and figure out where the sound is coming from.

http://www.amazon.com/Lisle-52500-Mecha ... tethoscope

You say you rebuilt it after a bottom end failure.

Did you use a whole new bottom end?

Was it machined or did you use std bearings?

How was it inspected?

Did the sound start right away?

Has it gotten worse?

Start by getting yourself a stethoscope and figure out where the sound is coming from.

http://www.amazon.com/Lisle-52500-Mecha ... tethoscope

You say you rebuilt it after a bottom end failure.

Did you use a whole new bottom end?

Was it machined or did you use std bearings?

How was it inspected?

Did the sound start right away?

Has it gotten worse?

Re: Tapping noise after rebuild on 4AGE small port

Thinkin' 'bout rod bearings there Yoshi? Maybe missed a bolt in torqueing the bolts?

One shot, one kill.

Re: Tapping noise after rebuild on 4AGE small port

Thanks for the feedback.

I had a big end bearing failure, the rod failed, went through the block, ruined the crank, piston.....etc

I ended up getting another bottom end from a different engine, replaced the rings, big end bearings, thrust bearings, main bearings, and seals.

I didn't replace the little end bearings though - do you think this could be it?

I had a big end bearing failure, the rod failed, went through the block, ruined the crank, piston.....etc

I ended up getting another bottom end from a different engine, replaced the rings, big end bearings, thrust bearings, main bearings, and seals.

I didn't replace the little end bearings though - do you think this could be it?

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: Tapping noise after rebuild on 4AGE small port

ChazzyB wrote:Thanks for the feedback.

I had a big end bearing failure, the rod failed, went through the block, ruined the crank, piston.....etc

I ended up getting another bottom end from a different engine, replaced the rings, big end bearings, thrust bearings, main bearings, and seals.

I didn't replace the little end bearings though - do you think this could be it?

So you used the whole new bottom end right?

Did you measure all the components to confirm it was all in spec or did you just throw bearings in it?

Re: Tapping noise after rebuild on 4AGE small port

I measured the crank diameters, then checked the clearances with plastigauge and everything was within tolerance. I checked the end float and that was within tolerance. The only thing I never did was take out the gudgeon pins and check the little ends.

The other thing I've probably done is put some of the valve springs in upside down.

The other thing I've probably done is put some of the valve springs in upside down.

Re: Tapping noise after rebuild on 4AGE small port

Worn pin bushings could be the culprit. What did the pistons look like? Did you measure the piston diameter and cylinder bore? Possible piston slap.

One shot, one kill.

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: Tapping noise after rebuild on 4AGE small port

Upsidedown springs shouldn't cause any noise. I don't know exactly what issues it would cause, I'm guessing it has more to to with the compression harmonics or something but I would try to fix that sooner than later.

I doubt it has anything to do with your sound though.

I would definitely get that stethoscope though and try to locate where the sound is coming from. The small ends could do this but it's pretty rare to see them get that loose.

I doubt it has anything to do with your sound though.

I would definitely get that stethoscope though and try to locate where the sound is coming from. The small ends could do this but it's pretty rare to see them get that loose.

- oldeskewltoy

- Club4AG MASTER

- Posts: 2214

- Joined: Wed Jan 09, 2013 4:44 pm

- Location: Portland, Oregon

Re: Tapping noise after rebuild on 4AGE small port

that is something light... that is not a rod... and I don't believe it is a piston slap...

I've not heard if running the springs upside down can cause noise... that doesn't mean it does... or doesn't.

Trying to isolate the noise using a stethoscope should get you close....

it sounds very valve train to me...... if the springs MIGHT be upside down... might they not have their steel spring seats???

I've not heard if running the springs upside down can cause noise... that doesn't mean it does... or doesn't.

Trying to isolate the noise using a stethoscope should get you close....

it sounds very valve train to me...... if the springs MIGHT be upside down... might they not have their steel spring seats???

OST Cyl head porting, - viewtopic.php?f=22&t=300

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

- gotzoom?

- Club4AG Expert

- Posts: 403

- Joined: Fri Jan 11, 2013 8:42 am

- Location: Silicon Valley, CA

- Contact:

Re: Tapping noise after rebuild on 4AGE small port

The valves will tick if the clearance is too tight. A couple of my valves are right at minimum spec and they tick when the engine warms up.

Re: Tapping noise after rebuild on 4AGE small port

Where are you based ? Love Donnington

Not many UK members on here though.

Try putting a long screwdriver handle to your ear, and then pressing the end on the block, will get you close to the area the noise is coming from.

Sounds like valves to me, pop off the cam covers and check all the steel spring seats are there, I'm guessing you've got 1 missing and that's a valve bouncing or something along those lines.

Not many UK members on here though.

Try putting a long screwdriver handle to your ear, and then pressing the end on the block, will get you close to the area the noise is coming from.

Sounds like valves to me, pop off the cam covers and check all the steel spring seats are there, I'm guessing you've got 1 missing and that's a valve bouncing or something along those lines.

Re: Tapping noise after rebuild on 4AGE small port

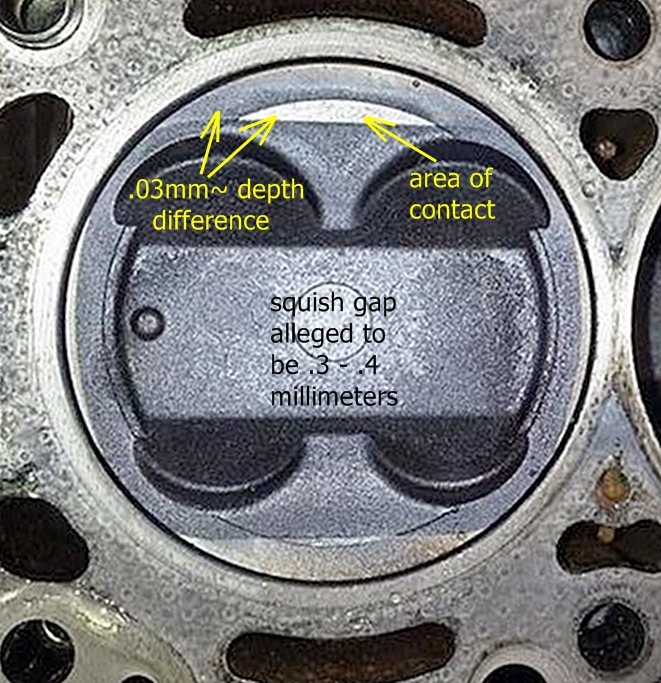

Thanks for all the feedback. I've got to the bottom of the problem, and it's been my own stupid fault. I thought back to everything that'd been done and it slapped me right in the face. I took the head off to confirm what I thought it probably was:

I had both the head and block skimmed when I first stripped the engine and then fitted a 0.8mm TRD head gasket. 0.5mm was taken off during the block skim, some more during the head, and then 0.4mm with the reduced thickness head gasket.....all this leads to head/piston contact at higher rpm when the rods start to stretch.

I really should have measured the squish clearance with some solder when I put it back together. Anyway, a standard thickness gasket it going on now which should bring it back to where I want it.

I had both the head and block skimmed when I first stripped the engine and then fitted a 0.8mm TRD head gasket. 0.5mm was taken off during the block skim, some more during the head, and then 0.4mm with the reduced thickness head gasket.....all this leads to head/piston contact at higher rpm when the rods start to stretch.

I really should have measured the squish clearance with some solder when I put it back together. Anyway, a standard thickness gasket it going on now which should bring it back to where I want it.

Re: Tapping noise after rebuild on 4AGE small port

When you have the piston at TDC how much is above the block ?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Re: Tapping noise after rebuild on 4AGE small port

I'd finish the teardown to see if there is any damage to the bearings or pistons. Even the slightest contact can cause hidden, and serious damage. If you had detonation, check the rings, they could break. Check the ring lands, if there are any collapsed you will have tighter clearances or even binding. Either could be a sign of fatigue and imminent failure. A little extra time now could save a lot of time and money later.

One shot, one kill.

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: Tapping noise after rebuild on 4AGE small port

Skimming the head won't effect squish gap.

I agree with the suggestion to measure deck clearance. On paper your numbers are very tight however the blocks tend to be a little on the tall side so in reality you may not be as bad as you think.

Were you able to see any contact marks on the pistons and head?

I would definitely also suggest inspecting the bottom end clearances.

I agree with the suggestion to measure deck clearance. On paper your numbers are very tight however the blocks tend to be a little on the tall side so in reality you may not be as bad as you think.

Were you able to see any contact marks on the pistons and head?

I would definitely also suggest inspecting the bottom end clearances.

- oldeskewltoy

- Club4AG MASTER

- Posts: 2214

- Joined: Wed Jan 09, 2013 4:44 pm

- Location: Portland, Oregon

Re: Tapping noise after rebuild on 4AGE small port

ChazzyB wrote: fitted a 0.8mm TRD head gasket. 0.5mm was taken off during the block skim.....all this leads to head/piston contact at higher rpm when the rods start to stretch.

As yoshi points out machining the head for the most part doesn't change squish. Machining the block does.

As sirdeuce points out... any contact isn't good... check your rod bearings for any damage

yoshimitsuspeed wrote:.

Were you able to see any contact marks on the pistons and head?

I can.....

Looking at the contact, I'd say the old TRD .5mm gasket on a brand new block was likely the hot set up... likely gave you close to .6+mm total squish

OST Cyl head porting, - viewtopic.php?f=22&t=300

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

- oldeskewltoy

- Club4AG MASTER

- Posts: 2214

- Joined: Wed Jan 09, 2013 4:44 pm

- Location: Portland, Oregon

Re: Tapping noise after rebuild on 4AGE small port

oldeskewltoy wrote:ChazzyB wrote:all this leads to head/piston contact at higher rpm when the rods start to stretch.

Got any views of the chamber side of your head???

Btw... GREAT information... I borrowed it and did a little to it......

OST Cyl head porting, - viewtopic.php?f=22&t=300

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

-

yoshimitsuspeed

- Club4AG MASTER

- Posts: 2084

- Joined: Sun Jan 13, 2013 1:18 pm

- Contact:

Re: Tapping noise after rebuild on 4AGE small port

Ah I totally missed that.

This is good info.

ChazzyB it would be awesome if you could measure how far the piston sticks above the deck to verify what your actual squish gap was.

This is good info.

ChazzyB it would be awesome if you could measure how far the piston sticks above the deck to verify what your actual squish gap was.

Re: Tapping noise after rebuild on 4AGE small port

will do - I'll measure it all up when I get it back together tonight.

cheers,

cheers,

- oldeskewltoy

- Club4AG MASTER

- Posts: 2214

- Joined: Wed Jan 09, 2013 4:44 pm

- Location: Portland, Oregon

Re: Tapping noise after rebuild on 4AGE small port

ChazzyB wrote:will do - I'll measure it all up when I get it back together tonight.

cheers,

please take a pic or two of the head over #1 chamber too.... please

OST Cyl head porting, - viewtopic.php?f=22&t=300

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Re: Tapping noise after rebuild on 4AGE small port

It's all back together now with a standard thickness gasket and unsurprisingly the noise has stopped.

I measured the deck height to the edge of the piston crown and it was 0.45mm.

here is a picture of the cylinder head:

Hopefully it's now good to go!

I measured the deck height to the edge of the piston crown and it was 0.45mm.

here is a picture of the cylinder head:

Hopefully it's now good to go!

Re: Tapping noise after rebuild on 4AGE small port

From memory I had 0.25 piston above block with a standard head gasket and haven't had issues as of yet.

Hope all goes well at high RPM for you

Sent from my iPhone using Tapatalk

Hope all goes well at high RPM for you

Sent from my iPhone using Tapatalk

- oldeskewltoy

- Club4AG MASTER

- Posts: 2214

- Joined: Wed Jan 09, 2013 4:44 pm

- Location: Portland, Oregon

Re: Tapping noise after rebuild on 4AGE small port

PDB wrote:From memory I had 0.25 piston above block with a standard head gasket and haven't had issues as of yet.

Hope all goes well at high RPM for you

Sent from my iPhone using Tapatalk

units? ASSUMING you mean millimeters... for if you mean inches... that would be a feat....

OST Cyl head porting, - viewtopic.php?f=22&t=300

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Building a great engine takes knowing the end... before you begin

Enjoy Life... its the only one you get!

Re: Tapping noise after rebuild on 4AGE small port

lol sorry yeah forgot you Yanks still old school. Just looked at my old scraps of paper, it was 0.22mm

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk