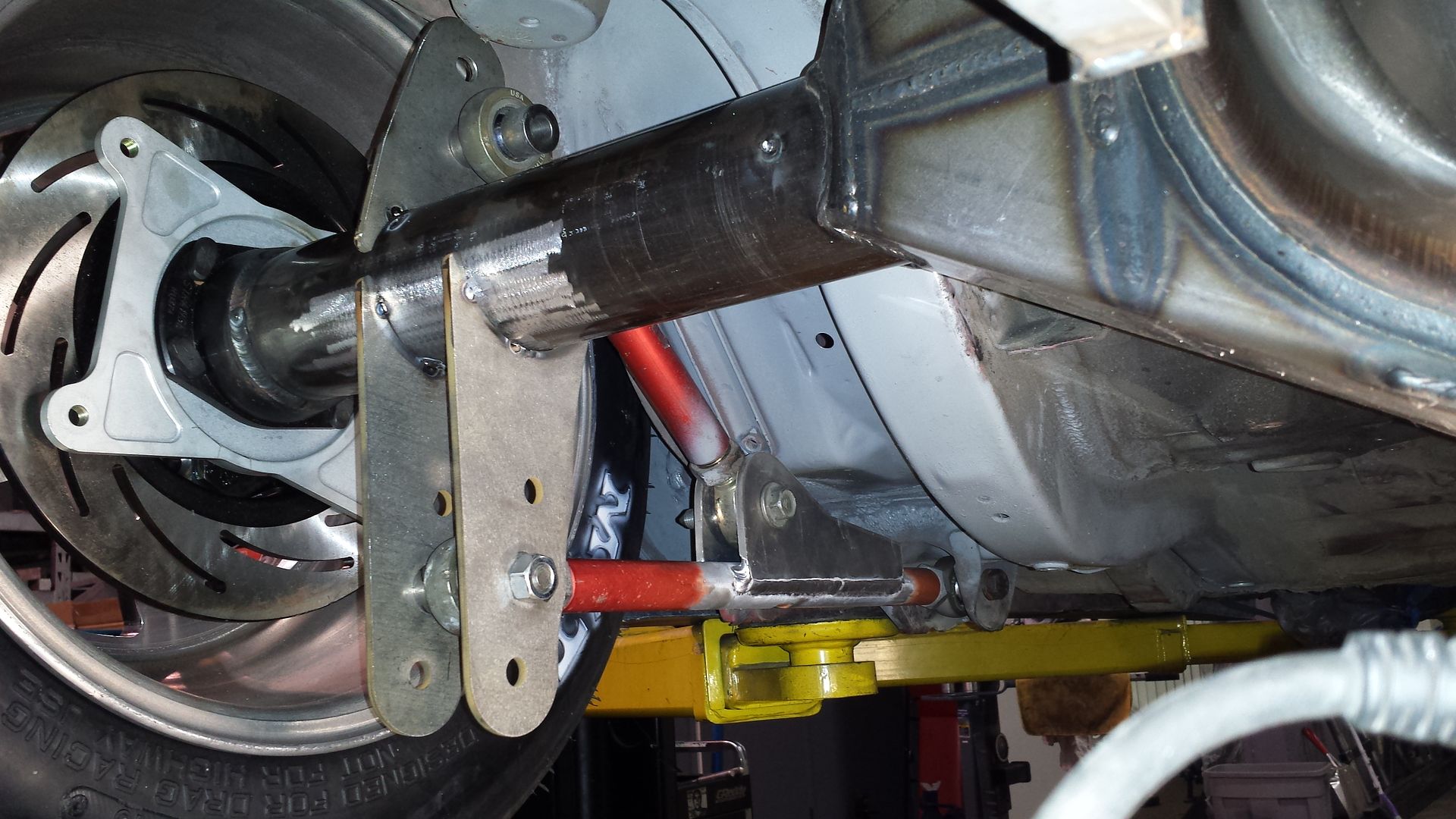

Because the holes that these install to in the factory axle bracket are

different sizes, the traction bracket needs special hardware. One spacer

tube that fits inside the factory bracket, and one that actually fits inside

the factory holes. If this hardware is not correct, the traction bracket

will be able to move under load... and it needs to be locked in position.

Notice also that there are three positions available for the end of the

lower trailing link to be secured. The holes should be slightly stepped

in an arc that follows the movement of the trailing link. These allow for

some tuning of the linkage geometry without changing the pinion angle.

Here are some (not the ones pictured above) installed...

So what do traction brackets do, and should I have them on my car ?

Traction brackets are loosely the rear axle equivalent of the bump steer

spacers (RCA's) that are installed in the front of your AE86 after you have

lowered the car by 40 or 50mm. Dropping the car throws the factory links

out of alignment, which has a negative effect on certain handling

characteristics. On the rear axle two separate settings are affected...

Pinion Angle

Because the AE86 has unequal length trailing links, as the axle moves up

and down, the top arm turns thru a smaller arc than the lower arm. This

causes the nose of the pinion shaft to pitch down as the car is lowered.

When this happens, the axis of the pinion is no longer parallel to the axis

of the front half of the drive shaft, and the universal joints no longer have

equal angles. This is not good for the universals. Pinion angle is corrected

by the use of adjustable length trailing links.

Trailing link Geometry

Real suspension geometry is way too complicated for me, but simplified

down, lowering the car changes the angle of the lower trailing link. This

is the link that is in compression when the car accelerates, explaining why

the lower arm is sturdy, while top arm (in tension) is skinny.

As the wheel rotates in one direction, the rear axle tries to rotate in the

opposite direction. This twisting motion is resisted by the lower trailing

link pressing against the short factory bracket. The force generated in the

link is transmitted to the chassis to accelerate the car. The angle of the

link determines how this force is applied to the car.

If the link angles down from its attachment point on the axle, then the

force will try and push the car down (push axle up). If it angles up, then

the force will try and push the car up (push axle down). Easy to figure

then that if the axle is being pushed down, the tires will be able to get

more grip. This is where the traction bracket comes in... by lowering

the attachment point, it brings the angle of the lower link back to where

the factory wanted it to be.

Axle Wrap - Wheel Hop

The factory trailing links are fitted with rubber bushings to keep noise

and vibration levels down. Unfortunately, rubber is also compressible,

and when subject to heavy loading as the rear axle tries to rotate under

acceleration, the bushings allow a degree of movement. Old, worn out

bushings allow more movement, and under heavy loading when the wheels

start to slip, a rapid cyclic rotation can occur in the rear axle.

This is experienced in the form of "wheel hop"... a violent jumping up

and down of the rear axle which really spoils that big skid you were trying

to lay down

Fresh hard rubber or poly bushings resist compression, and go a long way

towards eliminating wheel hop. Traction brackets also help by lengthening

the torque arm (distance of the link end from the axle tube), correcting

the angle of the lower arm, and in some cases, improving the pinion angle.

So, do you need traction brackets ? For moderately lowered cars (<30mm)

street cars... probably not. For more than 40mm down and competition

cars, there are definite benefits to be had from traction brackets used

with adjustable rear links.

Cheers... jondee86