Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Hey guys, I stalled out and luckily a nice mechanic saw me and helped get me some tools to unbolt the fuse box.

I was able to diagnose the issue further and it seems like if I unplug the 2A plug in the engine bay, power returns.

In the electrical diagram it shows that the 2a power source is pin 7 that connects to a short pin and then a 30A fl fuse. Anyone know where that is?

Found it. The 30A Fuse for the rotors are at the top left of the fuse box with a short pin right below it.

I was able to diagnose the issue further and it seems like if I unplug the 2A plug in the engine bay, power returns.

In the electrical diagram it shows that the 2a power source is pin 7 that connects to a short pin and then a 30A fl fuse. Anyone know where that is?

Found it. The 30A Fuse for the rotors are at the top left of the fuse box with a short pin right below it.

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Generally speaking, if you lose power because there is a short in the wiring,

it is quite easy to pinpoint... just look for the smoke and/or flames

So losing all power to important stuff indicates a break or non-functioning

relay. Looking at the #2A plug does not show that it powers anything that is

critical to engine function. But the #2E plug is the one that powers the EFI

once the key is switched ON. Test the EFI relay and make sure it does not

have any corrosion on the pins.

Cheers... jondee86

it is quite easy to pinpoint... just look for the smoke and/or flames

So losing all power to important stuff indicates a break or non-functioning

relay. Looking at the #2A plug does not show that it powers anything that is

critical to engine function. But the #2E plug is the one that powers the EFI

once the key is switched ON. Test the EFI relay and make sure it does not

have any corrosion on the pins.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Haha I didn't see any smoke. When I was able to reproduce the electrical issue, I tried removing all the fuses and relays. I still have 4-5V from fuse link to ground.

When I unplugged #2E, it didn't work the first time I unplugged it. But later on, when I unplugged it, it gave me power again.

I also noticed that with the #2E plugged in, when I unplugged #2A, power resumed.

I reseated the two plugs in, and I now it seems to be working correctly?

My friend came over today and helped me drive the car to an alignment shop without stalling. As he was driving I was tuning on the laptop. We got -57kPa to ~12kPa and 0-4000RPM tuned so it's not lean. Around -3kPa and above it goes too lean so I raised the inj timings there some more just now. Hopefully later I can test it out.

When I unplugged #2E, it didn't work the first time I unplugged it. But later on, when I unplugged it, it gave me power again.

I also noticed that with the #2E plugged in, when I unplugged #2A, power resumed.

I reseated the two plugs in, and I now it seems to be working correctly?

My friend came over today and helped me drive the car to an alignment shop without stalling. As he was driving I was tuning on the laptop. We got -57kPa to ~12kPa and 0-4000RPM tuned so it's not lean. Around -3kPa and above it goes too lean so I raised the inj timings there some more just now. Hopefully later I can test it out.

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

The #2A7 pin and the #2E5 are both powered up from the same red/blk wire

that originates at the fusible link block on the battery positive terminal. It

would be worth checking that you don't have a bad/loose connection at the

terminal.

AFAIK the only way you can get 4 or 5V in a 12V circuit, is to measure the

voltage between two resistances in series, that are connected between 12V

and ground. So working both ways from at the point you measure 4-5V, trace

the circuit and see what those resistances are ? It is very possible that one

will be a bad connection to power or ground.

Cheers... jondee86

that originates at the fusible link block on the battery positive terminal. It

would be worth checking that you don't have a bad/loose connection at the

terminal.

AFAIK the only way you can get 4 or 5V in a 12V circuit, is to measure the

voltage between two resistances in series, that are connected between 12V

and ground. So working both ways from at the point you measure 4-5V, trace

the circuit and see what those resistances are ? It is very possible that one

will be a bad connection to power or ground.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

I definitely shorted my igniter from the bolt that holds the red/black wire and ground before when I was working on ignitor stuff. (the fuse link bolt cover was semi-cracked) I think that has to be it. I'll check the resistance on the those circuits.

I was able to hack a way to log O2 sensor 0-5V wideband sensor into the ECU using the Trim signal in to record the voltage, and it's logging all the data I need to make changes! I also noticed that I may be able to use the wideband 5V directly as 02 sensor since there's an option to choose between 1V and 5V in the O2 sensor setup.

While my friend was here, we worked on bleeding the clutch and boy it grabs so much sooner now from when I let go of the clutch! It's pretty awesome! Before, it grabbed around 20% clutch pedal depress, now it catches around 70% clutch pedal press. There was a ton of random crap in the old brake fluid that was coming out.

I was able to hack a way to log O2 sensor 0-5V wideband sensor into the ECU using the Trim signal in to record the voltage, and it's logging all the data I need to make changes! I also noticed that I may be able to use the wideband 5V directly as 02 sensor since there's an option to choose between 1V and 5V in the O2 sensor setup.

While my friend was here, we worked on bleeding the clutch and boy it grabs so much sooner now from when I let go of the clutch! It's pretty awesome! Before, it grabbed around 20% clutch pedal depress, now it catches around 70% clutch pedal press. There was a ton of random crap in the old brake fluid that was coming out.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

I'm currently in the process of wiring up the wiper motor and I'm facing some issues. It looks like I'm always getting 11.9 voltage in the wiper motor wires always. I traced it down to the wiper and washer switch. When I opened up the back a little, it looks like there are some brown stains. I think it is corroded and who know's what else is corroded. Is it worth taking apart and fixing up? or would I keep on getting issues?

I found the part for around 55$ on some site. I was wondering if there is an alternative switch I could use from a different car? Thanks!

I found the part for around 55$ on some site. I was wondering if there is an alternative switch I could use from a different car? Thanks!

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

For the moment I think you would be better off just squirting some WD40

inside the switch and working it thru its range of operating movements about

50 times. With a bit of luck that will clean the contacts enough to allow you

to continue to use the existing switch. 11.9 volts is close enough to 12volts

and that is the nominal operating voltage, so the washer and wipers should

work OK.

Then put the wiper switch assembly on your list of things to look out for at

swap meets or junkyard visits. Sooner or later you will pick one up for just

a few bucks. Keep it as a spare and use it when the existing one dies.

Cheers... jondee86

inside the switch and working it thru its range of operating movements about

50 times. With a bit of luck that will clean the contacts enough to allow you

to continue to use the existing switch. 11.9 volts is close enough to 12volts

and that is the nominal operating voltage, so the washer and wipers should

work OK.

Then put the wiper switch assembly on your list of things to look out for at

swap meets or junkyard visits. Sooner or later you will pick one up for just

a few bucks. Keep it as a spare and use it when the existing one dies.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

What I mean is, in the off position, something is short circuiting so that the motor circuit gets 11.9V. I'm currently taking the switch apart to diagnose the issue.

EDIT: I took apart the switch assembly and created a circuit diagram for the wiper and washer switch w/ int to help with the diagnosis.

EDIT: I took apart the switch assembly and created a circuit diagram for the wiper and washer switch w/ int to help with the diagnosis.

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

I found this...

http://forums.toymods.org.au/index.php?t=msg&th=13120&&pl_view=&start=0#msg_106182

And this, which is interesting... and I want it

http://www.dorikaze.net/showthread.php?9154-Got-my-JDM-Variable-Int-Wiper-Switch

And this which is for wipers with the intermittent function...

In various places I have seen reference to a "wiper relay" and it is shown on this

diagram. But the way it is drawn leads me to believe that the "relay" components

are actually contained within the base of the switch. The diagram for the switch

without intermittent function is a little different.

Cheers... jondee86

http://forums.toymods.org.au/index.php?t=msg&th=13120&&pl_view=&start=0#msg_106182

And this, which is interesting... and I want it

http://www.dorikaze.net/showthread.php?9154-Got-my-JDM-Variable-Int-Wiper-Switch

And this which is for wipers with the intermittent function...

In various places I have seen reference to a "wiper relay" and it is shown on this

diagram. But the way it is drawn leads me to believe that the "relay" components

are actually contained within the base of the switch. The diagram for the switch

without intermittent function is a little different.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Thanks for looking! The first link looks like for a headlight switch and the circuitry there is quite different as the Wiper Switch (at least the one with int) is more complicated.

I saw the 2nd post as I was searching before, that variable INT switch is discontinued everywhere I looked. If you find one though, you know who needs one Hint: ME

Hint: ME

Here is my progress so far on repairing the one that came with the car.

Like my homemade 12V power source? haha. I ordered a breadboard and some jumper wires to help test this out. It's coming on Thursday.

EDIT: another question. I currently have the trigger angle to be 21 BTDC, however when I was talking with a Haltech rep sometime ago, they recommended me to go with 80-90. Should I reseat the distributor gear and make it 80-90? Since currently we're only using an ignition advance under 20 BTDC, it should be fine for now. I'm thinking in the future, when we need over 21 BTDC, would the ECU have trouble sending the timing signal to the ignitor?

I saw the 2nd post as I was searching before, that variable INT switch is discontinued everywhere I looked. If you find one though, you know who needs one

Here is my progress so far on repairing the one that came with the car.

Like my homemade 12V power source? haha. I ordered a breadboard and some jumper wires to help test this out. It's coming on Thursday.

EDIT: another question. I currently have the trigger angle to be 21 BTDC, however when I was talking with a Haltech rep sometime ago, they recommended me to go with 80-90. Should I reseat the distributor gear and make it 80-90? Since currently we're only using an ignition advance under 20 BTDC, it should be fine for now. I'm thinking in the future, when we need over 21 BTDC, would the ECU have trouble sending the timing signal to the ignitor?

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Hahahahahah  I was searching for wiper switch and that popped up. It

I was searching for wiper switch and that popped up. It

looked like a wiper switch and I didn't pick up the fact that it was a light

switch Never mind... it was a bit interesting any way.

Never mind... it was a bit interesting any way.

It also reminded me that there is only one washer pump, and that works

for both the front and rear wipers. When you operate the dash switch for

the rear washer, it energises the washer pump plus a flip-flop valve that

re-directs the flow from the front washer nozzles to the rear one.

I think way back I suggested 50-60deg as you will not have any reason to

go beyond 40deg BTDC total advance. I guess 80-90deg would also work.

Cheers... jondee86

looked like a wiper switch and I didn't pick up the fact that it was a light

switch

It also reminded me that there is only one washer pump, and that works

for both the front and rear wipers. When you operate the dash switch for

the rear washer, it energises the washer pump plus a flip-flop valve that

re-directs the flow from the front washer nozzles to the rear one.

I think way back I suggested 50-60deg as you will not have any reason to

go beyond 40deg BTDC total advance. I guess 80-90deg would also work.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Hi Jondee, actually, some cars (like my 1986 USDM hatch) came with not one but two motors for the washers.

Speaking of this, I once acquired an adjustable intermitent speed (slider? potentiometer?) washer button from a RHD car.

I've always wondered if there was a way to make the LHD one work with that potentiometer. I never found anyone that had done it but I'm curious... Just asking if you know anything about it

Sorry for the slight jack thread...

Sent from my iPhone using Tapatalk

Speaking of this, I once acquired an adjustable intermitent speed (slider? potentiometer?) washer button from a RHD car.

I've always wondered if there was a way to make the LHD one work with that potentiometer. I never found anyone that had done it but I'm curious... Just asking if you know anything about it

Sorry for the slight jack thread...

Sent from my iPhone using Tapatalk

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Ahhh.... I did see some stuff about two washer motors, but kind of

by-passed it, as my "Euro Spec" cars only ever had one plus the diverter

valve. If by slider you mean the rotary bezel that surrounds the wiper

switch, it should be possible to make it work.

That is pretty much the conversion that is described in one of the links

I posted above. The intermittent function basically just switches the low

speed motor on and off with a small timer circuit. AFAIK the wiper motor

is the same, just different switches.

I must have a look in my parts box and see if I have one lying around

Cheers... jondee86

by-passed it, as my "Euro Spec" cars only ever had one plus the diverter

valve. If by slider you mean the rotary bezel that surrounds the wiper

switch, it should be possible to make it work.

That is pretty much the conversion that is described in one of the links

I posted above. The intermittent function basically just switches the low

speed motor on and off with a small timer circuit. AFAIK the wiper motor

is the same, just different switches.

I must have a look in my parts box and see if I have one lying around

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

jondee86 wrote:I think way back I suggested 50-60deg as you will not have any reason to

go beyond 40deg BTDC total advance. I guess 80-90deg would also work.

Back then I didn't know I could reseat the distributor gear so that it doesn't match the OEM suggested alignment. I'll seat it to 50-60

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

So my breadboard came. I managed to burn out an LED while testing without the switch. Apparently you need at least a 1k ohms resistor in an LED circuit  After I tested lighting up an LED to see if I do have power. I connected up the switch with two other LEDs to indicate slow and fast motors.

After I tested lighting up an LED to see if I do have power. I connected up the switch with two other LEDs to indicate slow and fast motors.

https://www.youtube.com/watch?v=auip6wCN0Rw

The connector for the wiper motor is totally different than the harness connector. So I cut up the wiper motor and put the flat single connectors on. Heatshrinked around it, and then finally electrical tape all around the connection after I tested everything. Seems like it works

Here's a video of it in action:

https://www.youtube.com/watch?v=aR8InxmsSsY

https://www.youtube.com/watch?v=auip6wCN0Rw

The connector for the wiper motor is totally different than the harness connector. So I cut up the wiper motor and put the flat single connectors on. Heatshrinked around it, and then finally electrical tape all around the connection after I tested everything. Seems like it works

Here's a video of it in action:

https://www.youtube.com/watch?v=aR8InxmsSsY

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

aceforever wrote:btw I feel very comfortable about syncing up distributor and ECUs now!

It makes me feel pretty good

Yes... I'm sure it seemed rather daunting when you first pulled the ECU out

of the pizza box

and error, and now you can feel the satisfaction of having done something

that took you outside your comfort zone for a while !!

Cheers... jondee86

PS: What was wrong with the switch ?

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

It was shorted at the circuit board due to some rust. Scraped that off with a screw driver and it works again.

Haha yes! Now I'm not only fixing cars, I'm fixing stuff around the house too! Just took apart the dishwasher to figure out what was causing lots of particles on the dishes A lot of unscrewing later,I found the filter with tons of gunk to be cleaned off.

A lot of unscrewing later,I found the filter with tons of gunk to be cleaned off.

Yes... I'm sure it seemed rather daunting when you first pulled the ECU out

of the pizza boxBut a few months of DIY and learning with a bit of trial

and error, and now you can feel the satisfaction of having done something

that took you outside your comfort zone for a while !!

Haha yes! Now I'm not only fixing cars, I'm fixing stuff around the house too! Just took apart the dishwasher to figure out what was causing lots of particles on the dishes

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Guess what came in the mail today!

I got too excited and didn't order a baseplate and oil. If I was doing this for a profession, I would absolutely go bankrupt because I forget parts.

I got too excited and didn't order a baseplate and oil. If I was doing this for a profession, I would absolutely go bankrupt because I forget parts.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

So today, I was trying to sort out the speedometer issue.

At the instrument cluster side of the speedometer cable is a square bit.

At the gearbox side of the speedometer cable is a metal bit.

This metal bit goes into this housing that is hooked up to this plastic gear

As you can see my gear is very worn and that's probably why it isn't working. I'll go ahead and order a replacement since everything else was connected properly. I even checked to see if the metal bit transfers the spinning motion correctly to the plastic bit. Also tested it with the instrument cluster hooked up. Spinning the metal bit does indicate speed.

The problem is either the plastic gear being worn out, or some other issue with the gearbox. Either way, simplest way to test is to buy a replacement.

P.S. For future adventurers, when you pull out the plastic gear housing transmission fluid will leak out! Make sure you have a paper towel or rag handy to stop the fluid!

At the instrument cluster side of the speedometer cable is a square bit.

At the gearbox side of the speedometer cable is a metal bit.

This metal bit goes into this housing that is hooked up to this plastic gear

As you can see my gear is very worn and that's probably why it isn't working. I'll go ahead and order a replacement since everything else was connected properly. I even checked to see if the metal bit transfers the spinning motion correctly to the plastic bit. Also tested it with the instrument cluster hooked up. Spinning the metal bit does indicate speed.

The problem is either the plastic gear being worn out, or some other issue with the gearbox. Either way, simplest way to test is to buy a replacement.

P.S. For future adventurers, when you pull out the plastic gear housing transmission fluid will leak out! Make sure you have a paper towel or rag handy to stop the fluid!

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

The plastic gears have a few options on the number of teeth...

There should be a number stamped on the end... this one says 20.

Make sure you get the correct one or your speedo will not be reading

correctly. The other gear inside the gearbox is steel, so it will chew

up the plastic gear if the cable does not turn easily. If you can spin

it with your fingers you are good.

Cheers... jondee86

There should be a number stamped on the end... this one says 20.

Make sure you get the correct one or your speedo will not be reading

correctly. The other gear inside the gearbox is steel, so it will chew

up the plastic gear if the cable does not turn easily. If you can spin

it with your fingers you are good.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Thanks for reminding me. I've read up on these speedometer driven gears and in the US, there are two variations. 20 teeth for SR5 rear-end and 19 teeth for the GTS rear-end. The reason why there are two is because SR5 has different final gear than GTS rear-ends. I've made sure that my rear-end is the GT-S version by checking on the number of bolts on the drive side of the diff. GTS has 10 bolts, whereas the SR5 has 8bolts.

I've decided not to take out the gear out again and just go with 19, since that is supposed to be the right version for my car. Transmission oil is nasty stuff!

I've decided not to take out the gear out again and just go with 19, since that is supposed to be the right version for my car. Transmission oil is nasty stuff!

Last edited by aceforever on Sat May 30, 2015 6:28 pm, edited 2 times in total.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

I also got a chance to play with the horn / centering steering wheel.

I took apart the aftermarket steering hub and took a look. It seems like the positive track isn't connecting with the +12V coming from the horn. The hub adapter's positive track is too wide. Also found out that the center spline/bolt wasn't grounded. Not sure how it looks like on a normal hub. Will need to engineer something to ground the center. And probably look at getting a different hub adapter.

Good news is, I managed to center the steering wheel as much as I can.

I took apart the aftermarket steering hub and took a look. It seems like the positive track isn't connecting with the +12V coming from the horn. The hub adapter's positive track is too wide. Also found out that the center spline/bolt wasn't grounded. Not sure how it looks like on a normal hub. Will need to engineer something to ground the center. And probably look at getting a different hub adapter.

Good news is, I managed to center the steering wheel as much as I can.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

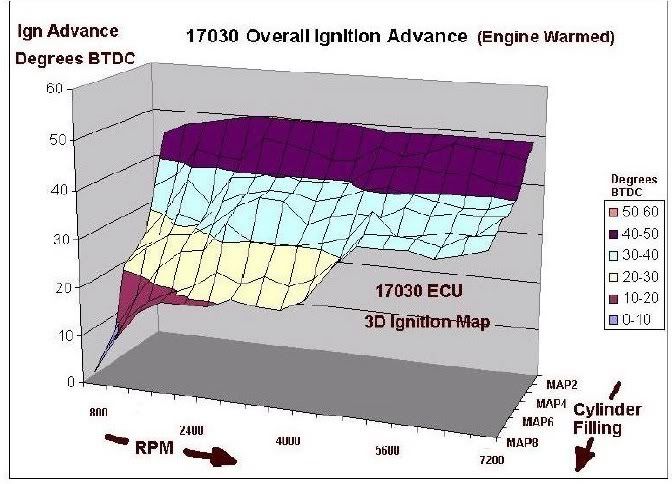

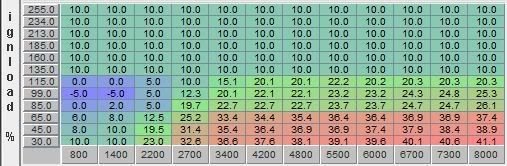

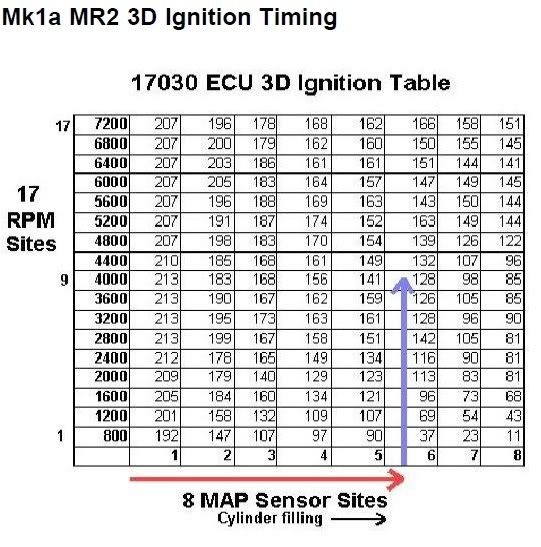

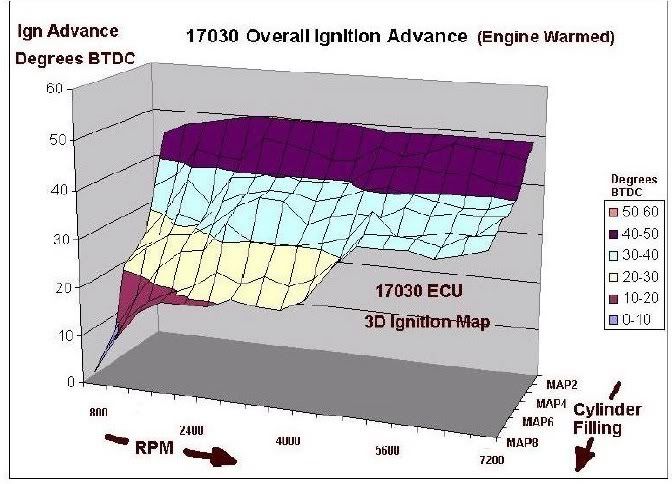

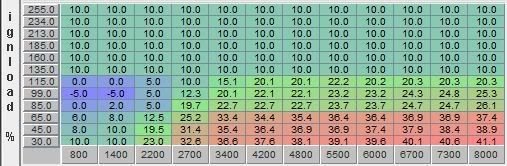

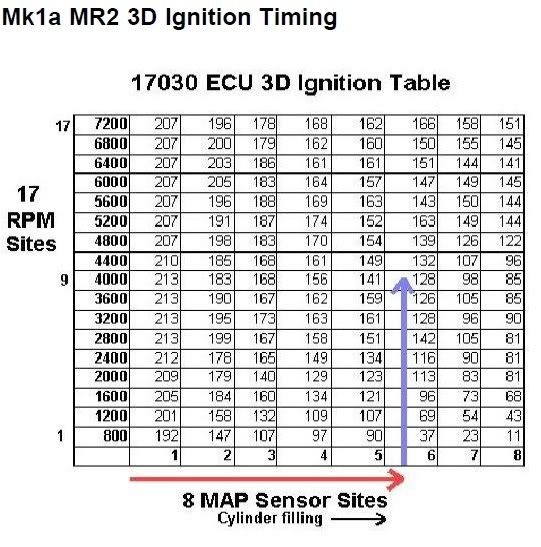

Looking at ignition maps and was trying to see what ignition timing does on an engine and what the relative change in ignition timing is when you go higher rpm and higher load.

Not sure but looking at some sample ign maps, it seems to me like higher load means more retard in ign timing, and lower load means more ign advance.

Higher RPM usually means more ignition advance but it varies less so than load.

From: http://www.aeu86.org/forum/showthread.php?tid=11876

From: http://forums.club4ag.com/zerothread?id=74402

And from what I understand based on information from videos and forums. Ignition timing greatly controls the power output of the engine. It also can cause rod knock (and I presume other bad things?) if tuned incorrectly.

The injector timing, to a certain extent, doesn't affect power output as much if kept within a range near 14.7 AFR.

In my case, I think tuning the engine so it's not running too lean or too rich for the highway drive to the tuner would suffice. Please correct me if I'm wrong.

Another question about going lean. Since there's always going to be a little latency in the ECU trying to compensate for extra air when changing throttle input quickly. Is it normal for AFR to go lean for a brief moment before it catches up and I get more fuel? What's the desired behavior here? I found that throttle pump settings only helps somewhat and cause the AFR to go rich after a brief moment after the initial leaning.

Not sure but looking at some sample ign maps, it seems to me like higher load means more retard in ign timing, and lower load means more ign advance.

Higher RPM usually means more ignition advance but it varies less so than load.

From: http://www.aeu86.org/forum/showthread.php?tid=11876

From: http://forums.club4ag.com/zerothread?id=74402

And from what I understand based on information from videos and forums. Ignition timing greatly controls the power output of the engine. It also can cause rod knock (and I presume other bad things?) if tuned incorrectly.

The injector timing, to a certain extent, doesn't affect power output as much if kept within a range near 14.7 AFR.

In my case, I think tuning the engine so it's not running too lean or too rich for the highway drive to the tuner would suffice. Please correct me if I'm wrong.

Another question about going lean. Since there's always going to be a little latency in the ECU trying to compensate for extra air when changing throttle input quickly. Is it normal for AFR to go lean for a brief moment before it catches up and I get more fuel? What's the desired behavior here? I found that throttle pump settings only helps somewhat and cause the AFR to go rich after a brief moment after the initial leaning.

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

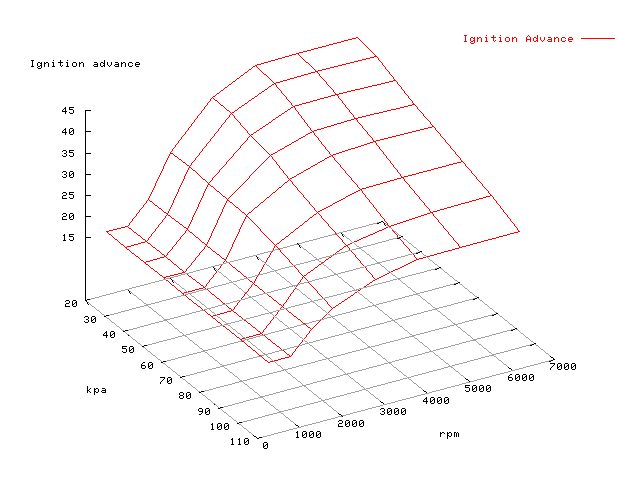

Here is a nice ignition map that fits in with my personal opinion of what

an ignition map should look like

Don't worry about the numbers on the axes as I don't know what engine this

map is for, and it doesn't matter. What is important is the shape of the map.

1. Because the combustion process needs to reach peak cylinder pressure at

a specific number of degrees after TDC for best torque, it follows that as the

engine rpm increases, the spark must be initiated earlier to allow time for

the combustion process to take place.

So we can say that ignition advance increases as rpm increases.

2. As the fuel load increases and the mixture becomes richer, the flame front

travels faster and the combustion process completes more quickly. This means

less advance is required when the engine is under heavy load.

So we can say that ignition advance decreases as load increases.

So you are correct in your understanding. And these two conflicting requirements

result in a ignition map shaped as shown above. Of course there are many ways

of making these simple rules seem complex and out of reach of ordinary mortals

However, countless millions of cars happily ran for billions of miles with a simple

mechanical distributor that used centrifugal weights to advance the ignition with

rpm and retard it with vacuum... no electronics required !!!

By using a sophisticated dyno it is possible to establish exactly the right amount

of advance for best torque at any particular combination of rpm and load. This

process will produce a "peaky" 3D map as shown in your post. But I have proven

that a car will run perfectly well with a basic "smooth" map, very much like the one

shown above.

Cheers... jondee86

an ignition map should look like

Don't worry about the numbers on the axes as I don't know what engine this

map is for, and it doesn't matter. What is important is the shape of the map.

1. Because the combustion process needs to reach peak cylinder pressure at

a specific number of degrees after TDC for best torque, it follows that as the

engine rpm increases, the spark must be initiated earlier to allow time for

the combustion process to take place.

So we can say that ignition advance increases as rpm increases.

2. As the fuel load increases and the mixture becomes richer, the flame front

travels faster and the combustion process completes more quickly. This means

less advance is required when the engine is under heavy load.

So we can say that ignition advance decreases as load increases.

So you are correct in your understanding. And these two conflicting requirements

result in a ignition map shaped as shown above. Of course there are many ways

of making these simple rules seem complex and out of reach of ordinary mortals

However, countless millions of cars happily ran for billions of miles with a simple

mechanical distributor that used centrifugal weights to advance the ignition with

rpm and retard it with vacuum... no electronics required !!!

By using a sophisticated dyno it is possible to establish exactly the right amount

of advance for best torque at any particular combination of rpm and load. This

process will produce a "peaky" 3D map as shown in your post. But I have proven

that a car will run perfectly well with a basic "smooth" map, very much like the one

shown above.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

aceforever wrote:In my case, I think tuning the engine so it's not running too lean or too rich for

the highway drive to the tuner would suffice. Please correct me if I'm wrong.

The ignition timing you already have programmed should be fine. And 14.7 AFR is

also fine for general round town running. You only need to start dialling in a bit

more fuel at big throttle openings and high rpm's.

Another question about going lean. Since there's always going to be a little

latency in the ECU trying to compensate for extra air when changing throttle input

quickly. Is it normal for AFR to go lean for a brief moment before it catches up and

I get more fuel? What's the desired behavior here? I found that throttle pump

settings only helps somewhat and cause the AFR to go rich after a brief moment

after the initial leaning.

It is likely that the E6X cannot inject extra fuel quickly enough to stop the lean

spike that follows a rapid throttle opening. More modern ECU's will inject the fuel

asynchronously,... that is to say, immediately, without waiting to add it to the next

scheduled injection event. If the extra fuel arrives late, then you will get a lean

spike followed by a rich spike.

I think the two controls you have available set the amount of fuel to inject, and

how quickly to inject it ? The "gain" control most likely responds to the TPS rate

of change, so if you still have some lag in your TPS response, that could be adding

to the "lateness" of the throttle pump action.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Thanks for walking me through some of the theory of ignition timing. I'll stick with the ones we programmed on for now and see what the tuner comes up with. I'm pretty interested in the theory behind the values. I'm also wondering what the process is of tuners when they do tune the ignition. I've heard from some places that you tune up until you hear a knock and then detune it down a bit. My ECU doesn't have a knock sensor so I presume the tuner needs to do it by ear? Or perhaps use a 3rd party knock sensor and hook it up to one of the connections on the ECU for data logging?

I didn't realize that the throttle pump correlates to the TPS values! That means it's very important for me to get the TPS signal to not have that delay issue. Thanks for the tip. I'll play with that. If even after that I can't get the ECU to inject extra fuel quickly, is it okay for that lean spike?

My base plate for the ITG filter came today. I'm trying to find a place to drill the holes out. I've made marks for the center of the holes and just need the machinery. Wish me luck!

I've also installed new wipers on the car. 17" and 19" RainX Latitudes work really well. I got them because came with a bunch of adapters and I wasn't sure which connector the car had. Apparently it's the Small J-Hook for future folks.

I didn't realize that the throttle pump correlates to the TPS values! That means it's very important for me to get the TPS signal to not have that delay issue. Thanks for the tip. I'll play with that. If even after that I can't get the ECU to inject extra fuel quickly, is it okay for that lean spike?

My base plate for the ITG filter came today. I'm trying to find a place to drill the holes out. I've made marks for the center of the holes and just need the machinery. Wish me luck!

I've also installed new wipers on the car. 17" and 19" RainX Latitudes work really well. I got them because came with a bunch of adapters and I wasn't sure which connector the car had. Apparently it's the Small J-Hook for future folks.

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Any decent tuner will have a "knock box" which will allow him to listen

for knock with headphones while tuning. Typically the system would consist

of a donut style knock sensor attached to the block using any suitable 8mm

threaded hole, an amplifier with selective noise filtering, and headphones.

If the dyno allows the engine to be held at a constant load and speed, the

tuner will adjust the timing to achieve best torque. He will do this at a number

of points and use these as a basis for your ignition map. Best torque will

usually be several degrees before the point where knock can be heard. If the

dyno does not allow for constant load holding, the tuner will make his best

guess at what advance you require. The difference in results between these

two approaches can be substantial.

The factory ECU will use the TPS to monitor the position of the throttle plate

to determine when the engine is at WOT and at idle. It uses the rate of change

in the position of the throttle plate for the throttle pump function.

A momentary lean spike will not harm the engine. Neither will a rich spike.

All that happens is that for that moment you have less than ideal combustion,

and the engine can tolerate that. I had exactly the same problem for some

time until I found the correct settings for the throttle pump. ITB's need a BIG

shot of extra gas when the throttle snaps open at low rpm, but little if any

extra gas after 3500rpm.

Yeah... good luck with making those holes. I did mine with a cheap holesaw

designed for cutting drywall. It was ugly

Cheers... jondee86

for knock with headphones while tuning. Typically the system would consist

of a donut style knock sensor attached to the block using any suitable 8mm

threaded hole, an amplifier with selective noise filtering, and headphones.

If the dyno allows the engine to be held at a constant load and speed, the

tuner will adjust the timing to achieve best torque. He will do this at a number

of points and use these as a basis for your ignition map. Best torque will

usually be several degrees before the point where knock can be heard. If the

dyno does not allow for constant load holding, the tuner will make his best

guess at what advance you require. The difference in results between these

two approaches can be substantial.

The factory ECU will use the TPS to monitor the position of the throttle plate

to determine when the engine is at WOT and at idle. It uses the rate of change

in the position of the throttle plate for the throttle pump function.

A momentary lean spike will not harm the engine. Neither will a rich spike.

All that happens is that for that moment you have less than ideal combustion,

and the engine can tolerate that. I had exactly the same problem for some

time until I found the correct settings for the throttle pump. ITB's need a BIG

shot of extra gas when the throttle snaps open at low rpm, but little if any

extra gas after 3500rpm.

Yeah... good luck with making those holes. I did mine with a cheap holesaw

designed for cutting drywall. It was ugly

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

As always, thanks for your knowledge and wisdom!

I've been reading the E6X manual and it shows this setting:

I think it's to compensate for TPS that bounce around when you're holding at a certain position. I don't know what the defaults are at this time. But I feel like this number should be pretty low for me.

Also something neat for when I face the atomspheric MAP. Seems like it's only good if I face atmospheric after 70% as that's the minimum

I've been reading the E6X manual and it shows this setting:

Throttle Pump Dead-band

This field defines the percentage change in throttle position that must occur before the

throttle pump is activated. This feature allows for “jitter” in the throttle that would

otherwise over-fuel the engine. The valid range of values is 1-20%.

I think it's to compensate for TPS that bounce around when you're holding at a certain position. I don't know what the defaults are at this time. But I feel like this number should be pretty low for me.

Also something neat for when I face the atomspheric MAP. Seems like it's only good if I face atmospheric after 70% as that's the minimum

Full Throttle Map

This feature allows the user to adjust a special fuel map that is used only when the

throttle is wide open on normally aspirated engines. With some manifold and or

throttle designs, pressures in the manifold can reach close to atmospheric pressure

before full throttle is applied. This effect can make tuning difficult around full

throttle. This map allows the full load settings to be easily set without interfering with

lighter load settings. This field enables or disables the use of this map.

Full Throttle Threshold

This field defines the throttle position at which the ECU considers to be full throttle.

This field can be set between 70 and 100.

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Throttle Pump Dead Band

This appears to be a way of "de-sensitizing" the throttle pedal so that

accidental small movements don't activate the throttle pump function.

In many driving situations, providing the throttle is used gently to increase

speed, there is no need for extra fuel. The change in manifold pressure

will automatically move the fuelling to a richer point on the fuel map.

If we use the original name of accelerator pump it makes it clear

that this function was designed to help avoid lean stumble when the engine

was being asked to accelerate the car. Sudden acceleration would call up

a big squirt of fuel, while slow acceleration would get little or no extra

fuel from the pump.

Full Throttle Map

This function addresses the major shortcoming of ITB's when used with

speed-density tuning. Because the MAP reading reaches atmospheric before

the throttles are fully open, it is difficult to tune the top end of the fuel map.

I have copied and pasted the above as it illustrates very well the problems that

can be encountered when tuning ITB's using the MAP sensor for load input. It is

not impossible to tune if the ITB's are correctly sized for the engine, and there

is a stable MAP signal. But if the ITB's are over-sized and the engine has bigger

cams than stock, a TPS tune is a much better option.

The default value for the Full Throttle Threshold is 95% so effectively what the

Full Throttle Map is designed to do is ensure that you have safe fuelling when

the engine is at WOT. This is not unusual as the stock ECU runs in open loop at

WOT for the same reason.

Cheers... jondee86

This appears to be a way of "de-sensitizing" the throttle pedal so that

accidental small movements don't activate the throttle pump function.

In many driving situations, providing the throttle is used gently to increase

speed, there is no need for extra fuel. The change in manifold pressure

will automatically move the fuelling to a richer point on the fuel map.

If we use the original name of accelerator pump it makes it clear

that this function was designed to help avoid lean stumble when the engine

was being asked to accelerate the car. Sudden acceleration would call up

a big squirt of fuel, while slow acceleration would get little or no extra

fuel from the pump.

Full Throttle Map

This function addresses the major shortcoming of ITB's when used with

speed-density tuning. Because the MAP reading reaches atmospheric before

the throttles are fully open, it is difficult to tune the top end of the fuel map.

My first attempt at tuning was to use SD only tuning, relying on the MAP

signal to determine how much fuel to provide for a given RPM. My reasoning

was that in the low to mid RPM area of operation, the 15% to 20% MAP range

was greater than the 5% to 10% throttle range that I would be using. Since I

wanted the best fuel control possible below about 3500 RPM this seemed

like a good choice.

I configured my VE table based on recommendations on the MS forums so

that over half the table was dedicated to the MAP region above 80%. In fact,

I split the MAP range from 92% to 100% into 5 rows of 2% increments.This

method worked ok at lower RPMs and small throttle openings. The mixture

was maintained fairly well under these conditions.

Over about half throttle or high RPMs this method was not ideal. In the upper

RPM portion of the table, I had more than 10% changes in fuel required from

just a 2% change in MAP. This made the tune incredibly sensitive to noise on

the MAP signal. As a result, the VE table would bounce around several bins

creating inconsistent fueling and mixture.

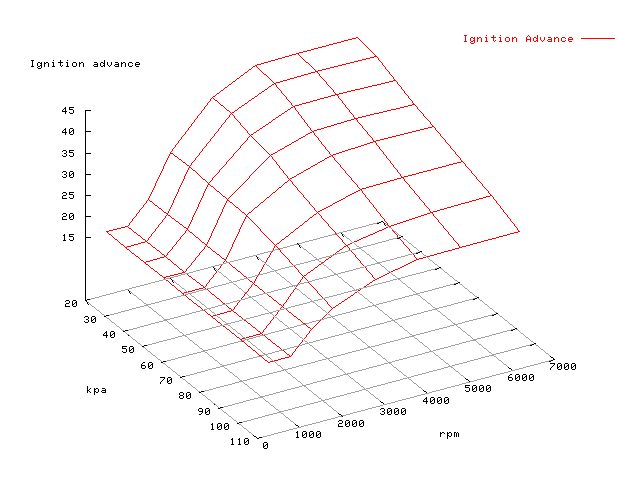

Here is the last VE table I used for SD only tuning. This was run on the 45mm

ITBs with my 2.0L engine.

VE table for SD only tuning. Notice that 2/3 of the table is dedicated to the

MAP region of greater than 80% with almost all VE increase occurring only in

the upper 15% of the MAP range.

A 3D view of the same VE table. This view really shows the nature of the ITBs

relative to MAP. You are trying to tune an engine using only 15% of the available

MAP signal. Notice the steep slope of the curve where large fuel changes are

made over just a 2% change in MAP signal.

I have copied and pasted the above as it illustrates very well the problems that

can be encountered when tuning ITB's using the MAP sensor for load input. It is

not impossible to tune if the ITB's are correctly sized for the engine, and there

is a stable MAP signal. But if the ITB's are over-sized and the engine has bigger

cams than stock, a TPS tune is a much better option.

The default value for the Full Throttle Threshold is 95% so effectively what the

Full Throttle Map is designed to do is ensure that you have safe fuelling when

the engine is at WOT. This is not unusual as the stock ECU runs in open loop at

WOT for the same reason.

Cheers... jondee86

The reasonable man adapts himself to the world; the unreasonable one

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

persists in trying to adapt the world to himself. Therefore, all progress

depends on the unreasonable man.

-

aceforever

- Club4AG Pro

- Posts: 637

- Joined: Sun Jan 18, 2015 11:36 am

- Location: Seattle, WA, USA

Re: Restoring AE86 w/ 4AGE 16v + HKS ITB + Haltech E6X

Thanks for walking me through tuning for WOT. I'll have to play around with it after I get the air filter on.

Update:

I was able to drill out the holes for the baseplate. However I did drill one screw hole a bit off and now it might leak air in. I'm thinking of using gasket maker to seal that up. Would the vacuum suck that in? I feel like if I shape the gasket in the shape of a grommet, there should be enough material that it wouldn't be able to pull the gasket in.

Currently taking TPS apart to see if I can clean out the contacts.

Update:

I was able to drill out the holes for the baseplate. However I did drill one screw hole a bit off and now it might leak air in. I'm thinking of using gasket maker to seal that up. Would the vacuum suck that in? I feel like if I shape the gasket in the shape of a grommet, there should be enough material that it wouldn't be able to pull the gasket in.

Currently taking TPS apart to see if I can clean out the contacts.