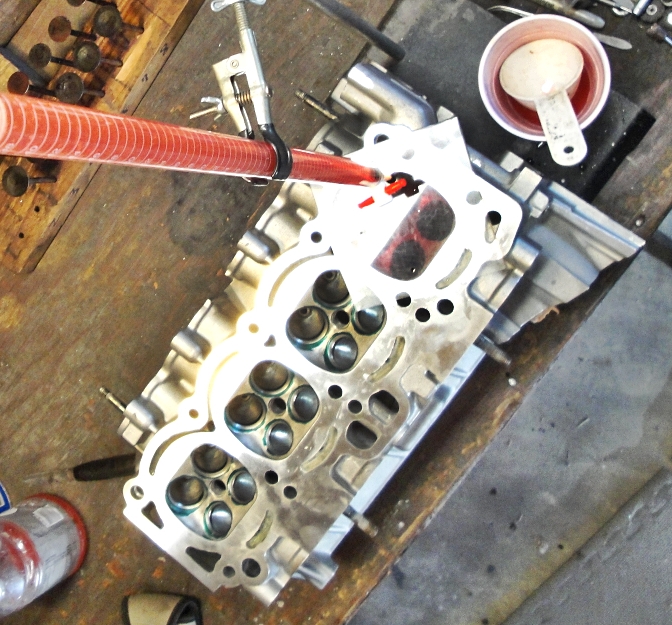

from another forum wrote:I had to tip the valves on the head I just rebuilt for my FX16 after the valve job.

I had at least 5-6 valves that were too tight for the thinnest shims I had on hand.

I didnt want to drive all the way back to the machine shop twice and wait around so I improvised.

I placed a piece of 1000 grit sand paper on a glass table top and worked the stems of the valves by hand to tip them. I calculated how much I needed to take off each one then used a micrometer to measure.

a little time consuming but it worked out very well.

You can also do the same with the shims...... I have about 100 3.0mm shims... thinking of using the shops shim grinder, and then finish with 1000... make my own batch of thin shims - down to 2.3mm or so

Toy86 wrote:Hey OST,

I'm an avid reader of your post and the knowledge you drop on us on here, it's very useful and informative. But I do have a question about the physics of how porting and polishing works, cuz I've heard of two different theories behind it.

Theory one is that the smoothing and expanding of the combustions cambers, intake and exhaust ports will prevent the atomization of the fuel and the swirling vortex that should be created by the factoring casting.

Theory two is just the opposite of theory one. Can you please explain of correct operations of the work you do? Thanks a ton!

Great question! Many people have earned their masters, or doctorate writing on this very subject.

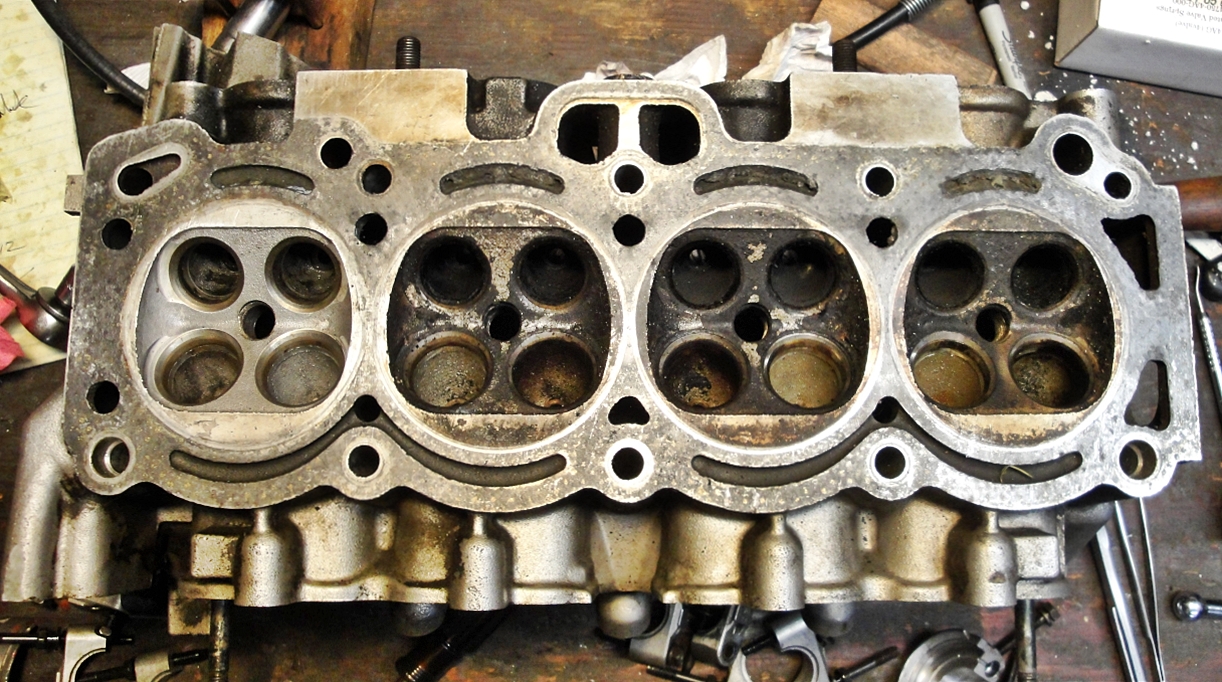

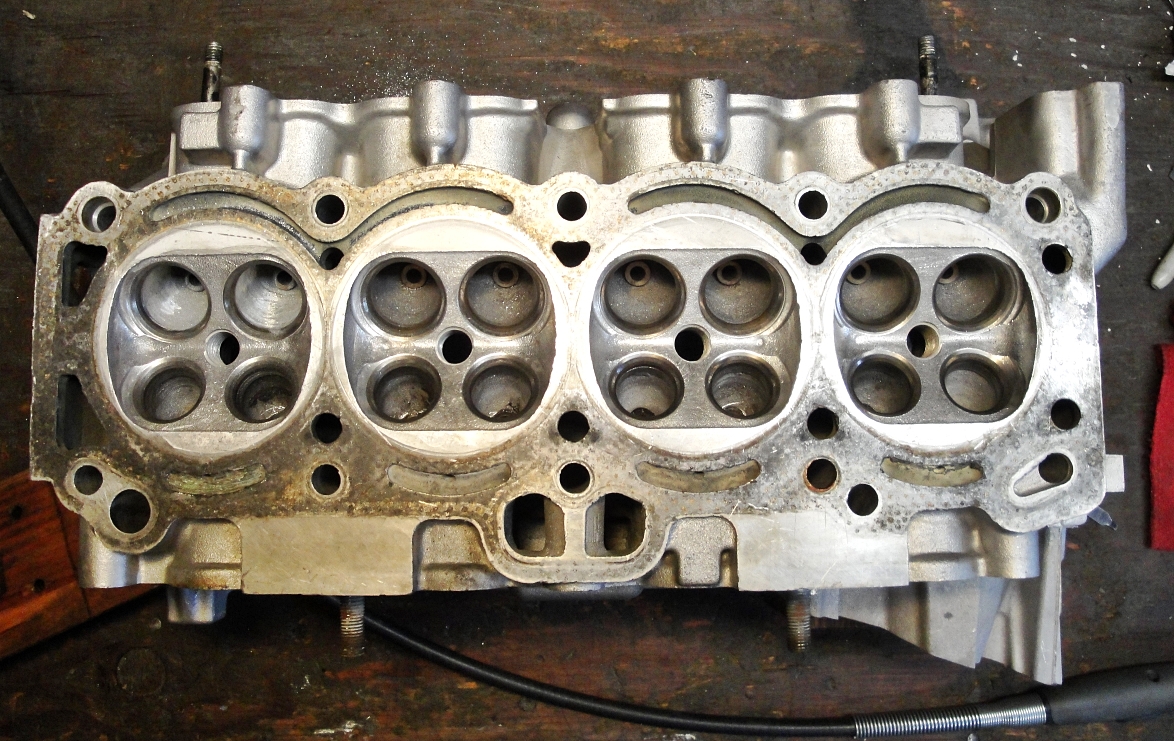

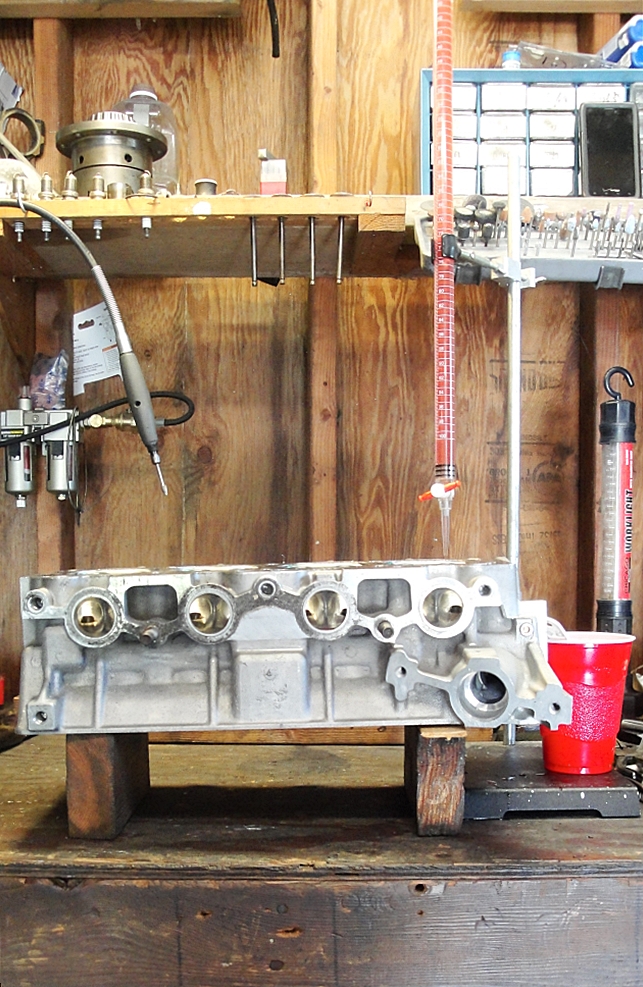

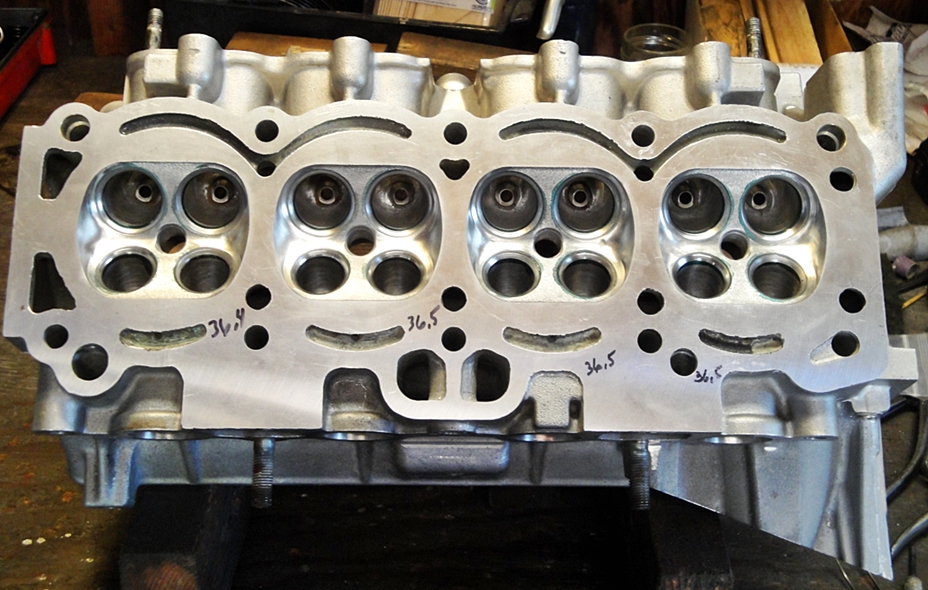

My education in the subject began when I built the engine for Surreptitious. Using the TRD Bible as a guide, I worked the combustion chambers to minimize all the sharp edges caused by the factory machining. I then brought the head to Loynings Engine Service... a well known Formula Atlantic builder. It was there I began to build a relationship with the shop. I was allowed in, and allowed to see the Atlantic heads upclose. I spoke to their lead head porter and he gave me some advice and offered some guidance. The rest I've gleaned from many other sources..... I'm a member of a number of forums where I'm the one doing most of the learning

The 2 theories... a) are nearly moot when discussing a 4AG

E. This is because the fuel is only added directly above the valves in a 4AGE, in a carbureted application this might be more of a concern since the air and fuel are mixed and travelling through the ports together... BUT

Most people who argue/discuss atomization, or laminar flow tend to minimize the effect of the dynamics of an engine. These dynamics are the airflow is NOT consistent... the airflow in an engine is dynamic it moves toward the valve, stops, moves a little away, and then moves toward/past the valve into the engine. This means the air stream is not flowing, but is more like the dance called the bunny hop... 3 steps forward, 2 steps back.... It is harder to say it helps atomizes, or laminar flow when the airflow is not smooth, but buffetted.

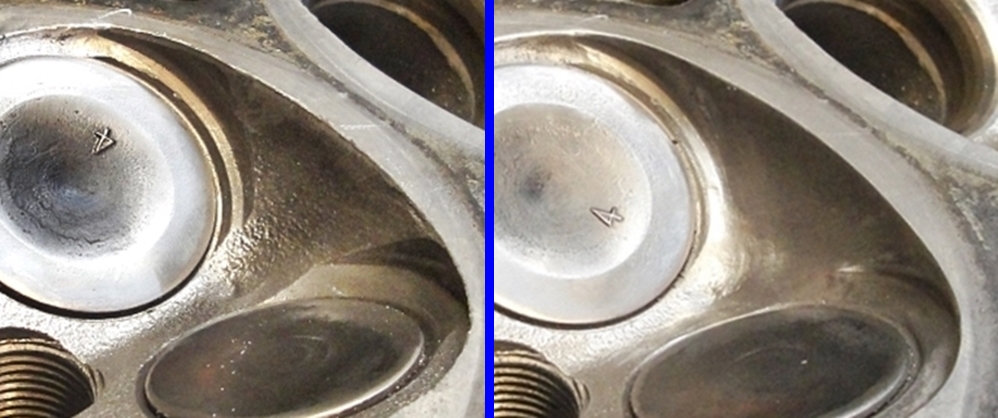

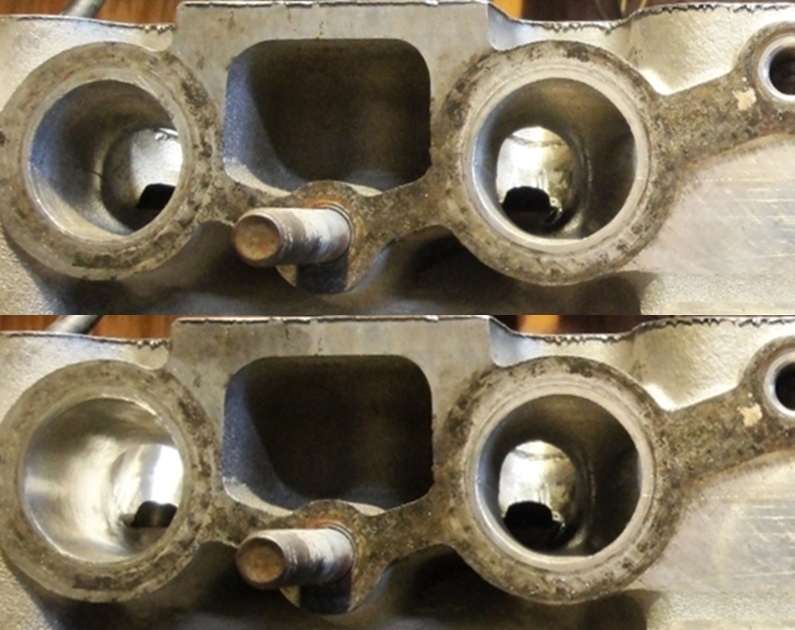

b)removing too much material from the chamber is a bad thing... you lose something called port reversion but removal of some material is required so you can remove hot spots from the chamber that cause ping/pre-ignition. A simple explanation of port reversion is a valve opening inside a funnel, the valve opening is always a metered opening thus keeping velocity up as the valve opens. So it is a trade off, the fact that the 4AG head is cast as it is means there is more advantage to CAREFUL material removal so that compression can be raised increasing the engines ability to make power. Port reversion tends to lessen as the valve angle increases. Port reversion works great on LS, or other engines were the valve angle is less then 15 degrees, the effects of port reversion lessen as the valve angle increases. The 4AGE has steep valve angles.

Now as far as my bowl and seat work, I'm mostly fixing flaws that occur because the head is a mass produced part destined for corporate profit, so flaws creep into the equation. I remove the flaws. Now as an example of why flaw removal is important, someday watch a stream, or brook, watch how the water interacts with the stream bank, watch the eddy currents, now watch a water slide... no eddy currents....

So, I've discussed the bowls and seats, and chamber deshrouding... but I have not yet discussed my exhaust port re-taper....

I was allowed in, and allowed to see the Atlantic heads upclose.