ebaY high comp oversize pistons - TC2989-.020 Dana

Posted: Mon May 18, 2015 3:51 pm

About a week ago I ordered a set of the $45 ebay 81.5 (.020 oversize) high comp pistons.

I took a very close look and there are a few problems, nothing serious, but issues requiring attention for them to be equal of their Toyota counterparts. This procedure will run me about $120 to "fix" the $45 pistons... along with a required block decking (another $100)

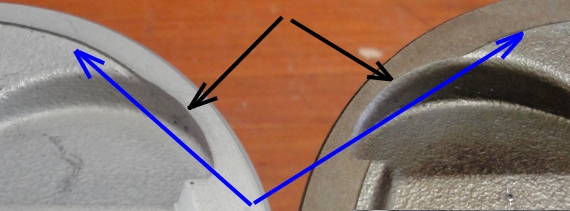

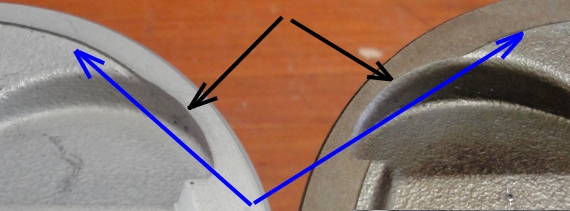

On the right is the Toyota piston, on the left the Dana. They look pretty good.... so why will they cost me an extra $120+?

Lets look a bit closer......

There are a few flaws that need addressing. The first is the blue lines are pointing out that that squish on the aftermarkket piston is further back from the head. .4mm further back. This means I'll have a wide squish gap... this is no good, so the piston will get machined down .4mm so the machined surface, and the cast surface are level.

In addition.... the aftermarket piston is also .4mm shorter before it gets machined! So... if I want a zero deck, the aftermarket piston will require me to machine the blocks deck nearly .8mm. At least I'll have a good surface to mate a MLS gasket too....

Finally the black arrows are pointing out the less then perfect finish to the valve relief. So once these pistons get machined, they will also get worked by hand so the valve reliefs have their full radius...

As to why the aftermarket piston has these "flaws".... a machinist I sometimes use explained it to me as follows, the oversize raises the compression, so they "adjust" a few other specs to keep static CR at the same it was before the overbore.

I took a very close look and there are a few problems, nothing serious, but issues requiring attention for them to be equal of their Toyota counterparts. This procedure will run me about $120 to "fix" the $45 pistons... along with a required block decking (another $100)

On the right is the Toyota piston, on the left the Dana. They look pretty good.... so why will they cost me an extra $120+?

Lets look a bit closer......

There are a few flaws that need addressing. The first is the blue lines are pointing out that that squish on the aftermarkket piston is further back from the head. .4mm further back. This means I'll have a wide squish gap... this is no good, so the piston will get machined down .4mm so the machined surface, and the cast surface are level.

In addition.... the aftermarket piston is also .4mm shorter before it gets machined! So... if I want a zero deck, the aftermarket piston will require me to machine the blocks deck nearly .8mm. At least I'll have a good surface to mate a MLS gasket too....

Finally the black arrows are pointing out the less then perfect finish to the valve relief. So once these pistons get machined, they will also get worked by hand so the valve reliefs have their full radius...

As to why the aftermarket piston has these "flaws".... a machinist I sometimes use explained it to me as follows, the oversize raises the compression, so they "adjust" a few other specs to keep static CR at the same it was before the overbore.