Flywheel bolts... the lowdown...

Posted: Thu Aug 25, 2016 2:32 am

After spending a couple of hours looking for a set of one-time used flywheel

bolts that I put safely away so that they wouldn't get lost... I gave up and

ordered a set of ARP bolts. This got me thinking about what sort of guidelines

should be applied when deciding whether or not to upgrade the more important

bolts that hold an engine together.

For example, the Toyota OEM flywheel bolts are a well made quality item, and

I had fully intended cleaning and reusing them. However, since I couldn't find

them, I did a bit of reading to see if I could find any techincal articles on just

how increasing the torque/power transmitted by the clutch affects the stress

on the flywheel bolts.

Not unsurprisingly, I found a lot of psuedo-technical BS from people selling

fancy bolts; a ton of opinions from people who wouldn't know a high tensile

bolt from a tuning fork; the usual hand wringing from the merchants of doom

who think reusing a bolt is certain to allow some part of your vehicle to fly

apart at high speed causing death and destruction. But no real tech stuff

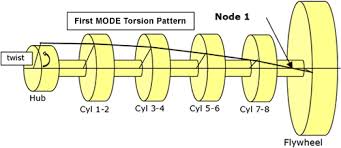

It seems that this is a subject not much researched, and one where there is

more misinformation than hard fact. Flywheel bolts can fail for a variety of

reasons... over tightened, under tightened, wrong bolt for the job, too short,

too long, used a washer, didn't use a washer etc. But more interesting is the

possibility that the number of cylinders can have a major effect... 4-cylinder

engines being the worst for vibration.

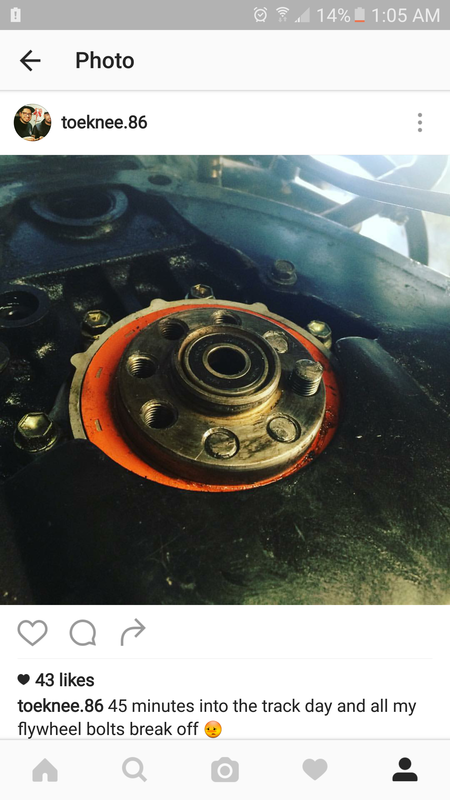

So to the point Who has had a problem with flywheel bolts, and did the

Who has had a problem with flywheel bolts, and did the

problem relate to using OEM bolts on a high revving NA or turbo engine ?

Let me hear the horror stories from all you one-legged guys

Cheers... jondee86

bolts that I put safely away so that they wouldn't get lost... I gave up and

ordered a set of ARP bolts. This got me thinking about what sort of guidelines

should be applied when deciding whether or not to upgrade the more important

bolts that hold an engine together.

For example, the Toyota OEM flywheel bolts are a well made quality item, and

I had fully intended cleaning and reusing them. However, since I couldn't find

them, I did a bit of reading to see if I could find any techincal articles on just

how increasing the torque/power transmitted by the clutch affects the stress

on the flywheel bolts.

Not unsurprisingly, I found a lot of psuedo-technical BS from people selling

fancy bolts; a ton of opinions from people who wouldn't know a high tensile

bolt from a tuning fork; the usual hand wringing from the merchants of doom

who think reusing a bolt is certain to allow some part of your vehicle to fly

apart at high speed causing death and destruction. But no real tech stuff

It seems that this is a subject not much researched, and one where there is

more misinformation than hard fact. Flywheel bolts can fail for a variety of

reasons... over tightened, under tightened, wrong bolt for the job, too short,

too long, used a washer, didn't use a washer etc. But more interesting is the

possibility that the number of cylinders can have a major effect... 4-cylinder

engines being the worst for vibration.

So to the point

problem relate to using OEM bolts on a high revving NA or turbo engine ?

Let me hear the horror stories from all you one-legged guys

Cheers... jondee86