thanks guys...........

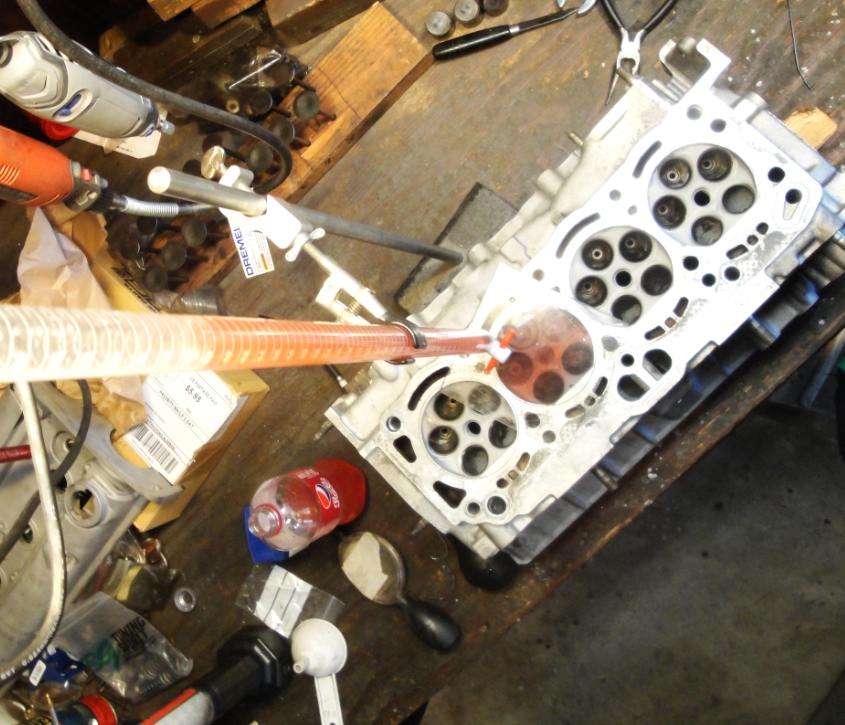

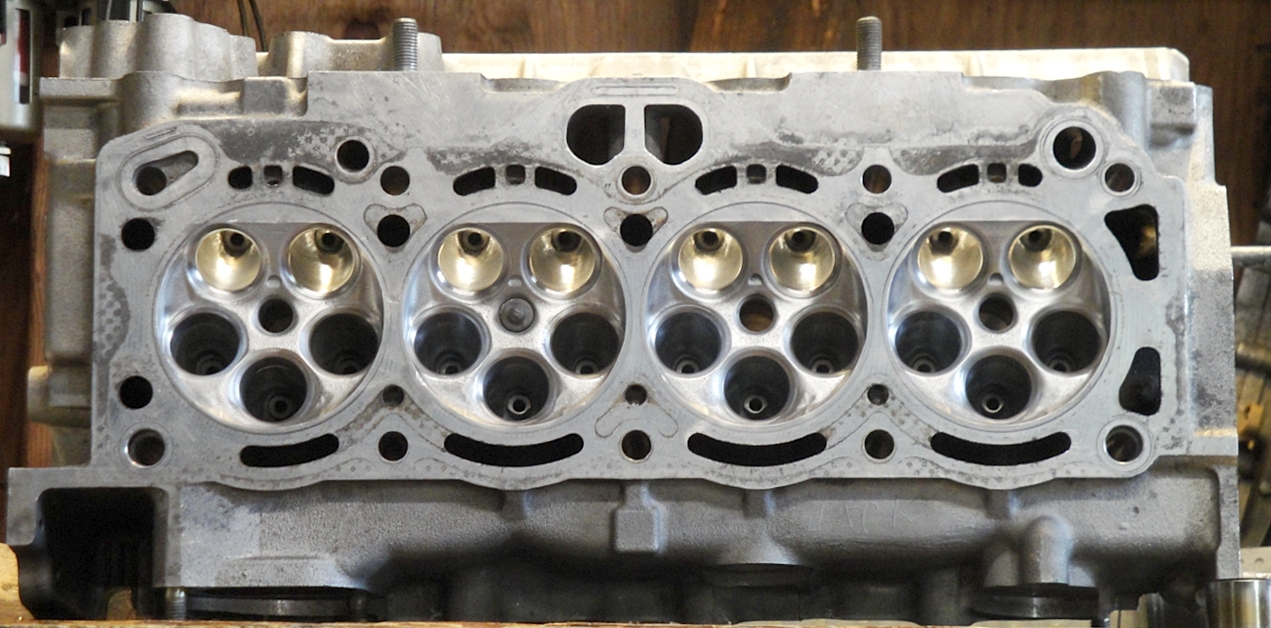

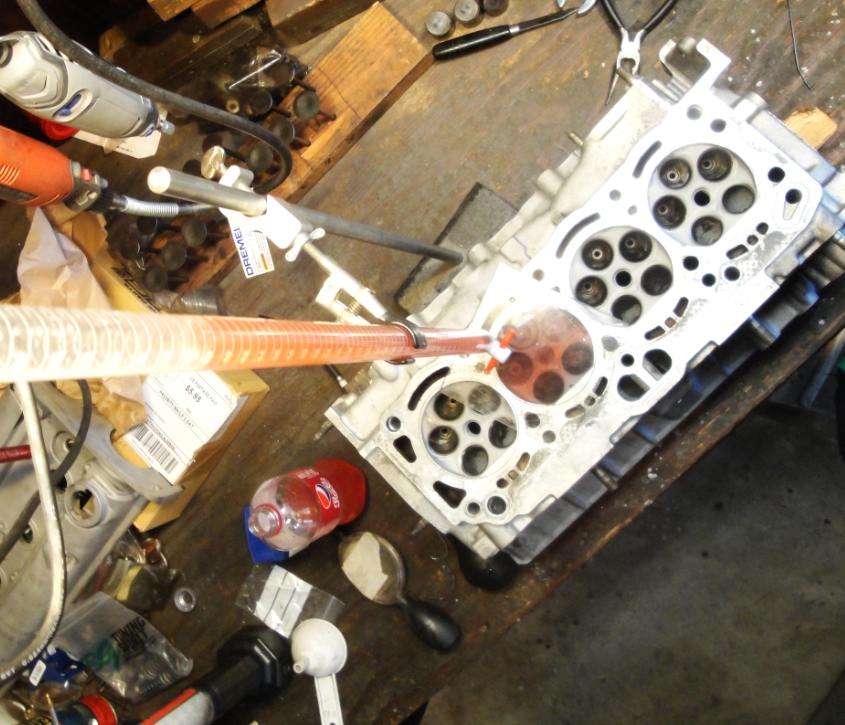

so once unwrapped and set up on the bench.... inspection begins....

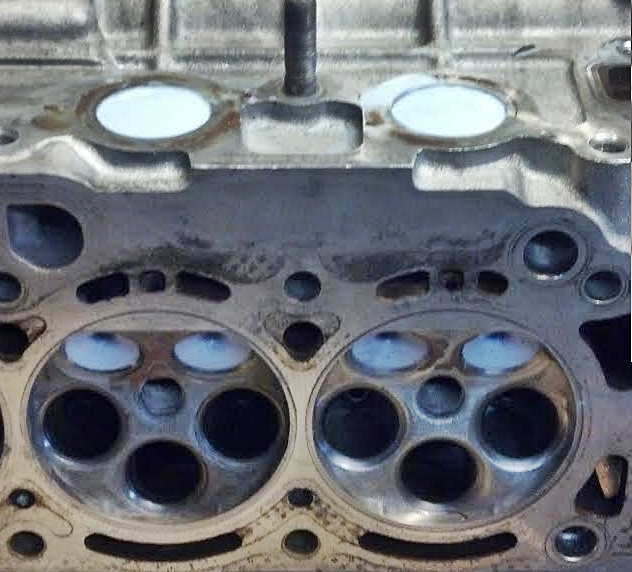

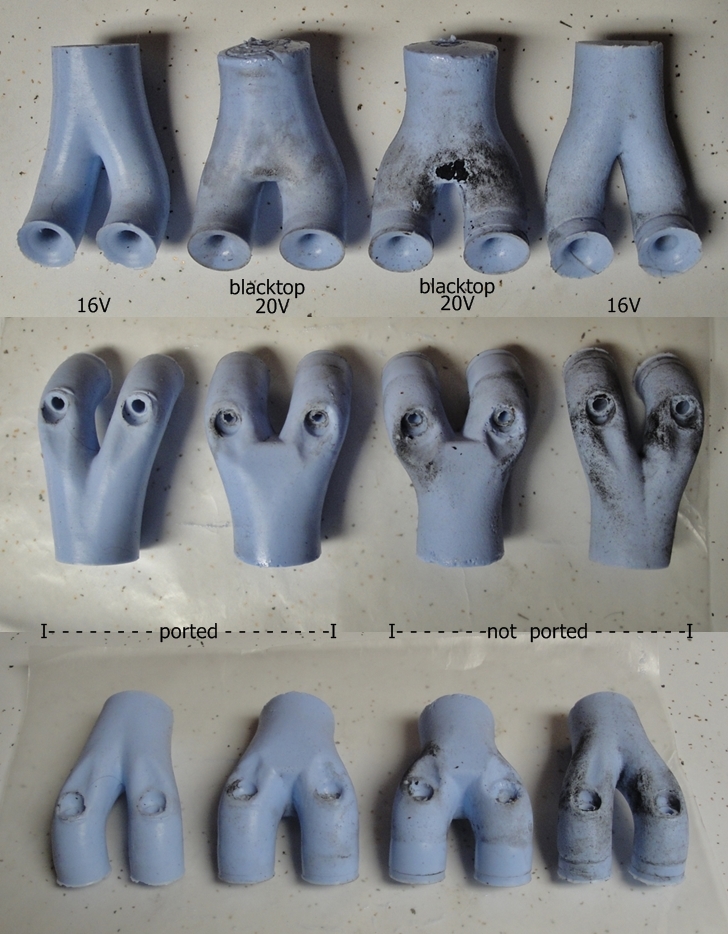

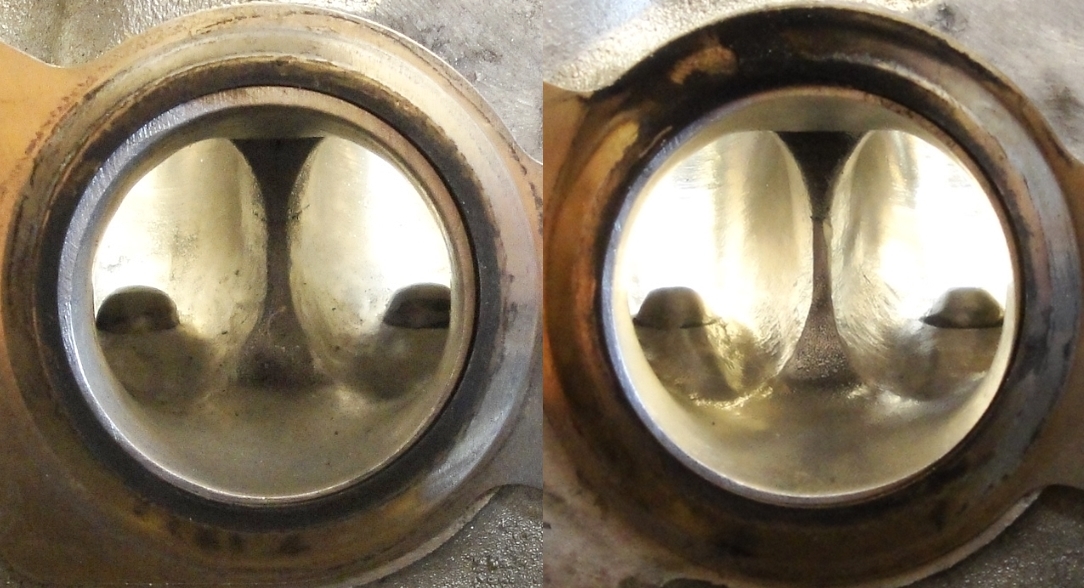

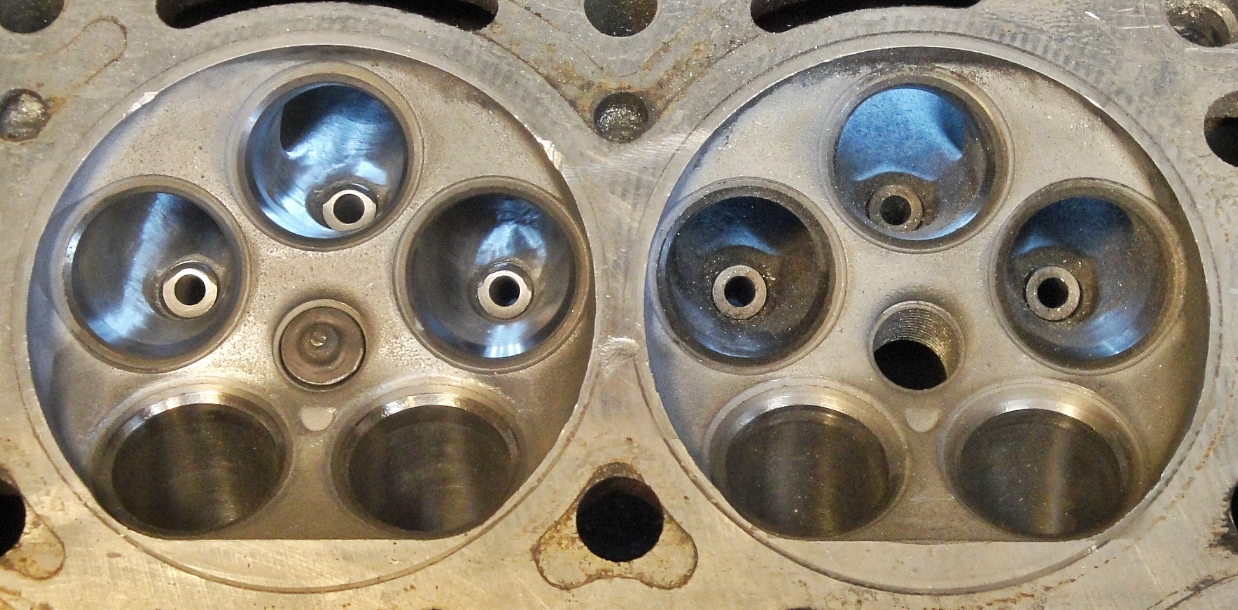

Over all the casting quality has gotten much better. Although there still is port-bowl-seat shift, the shift amount - at least in this head, is minimal.

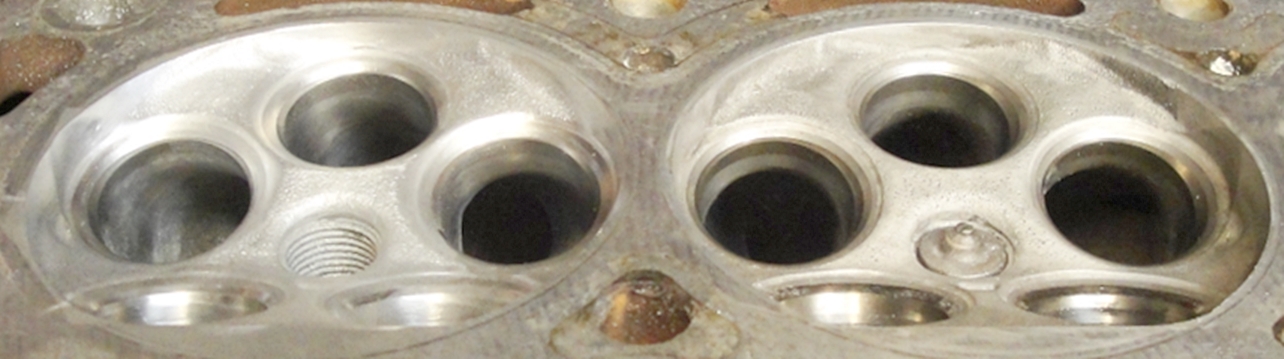

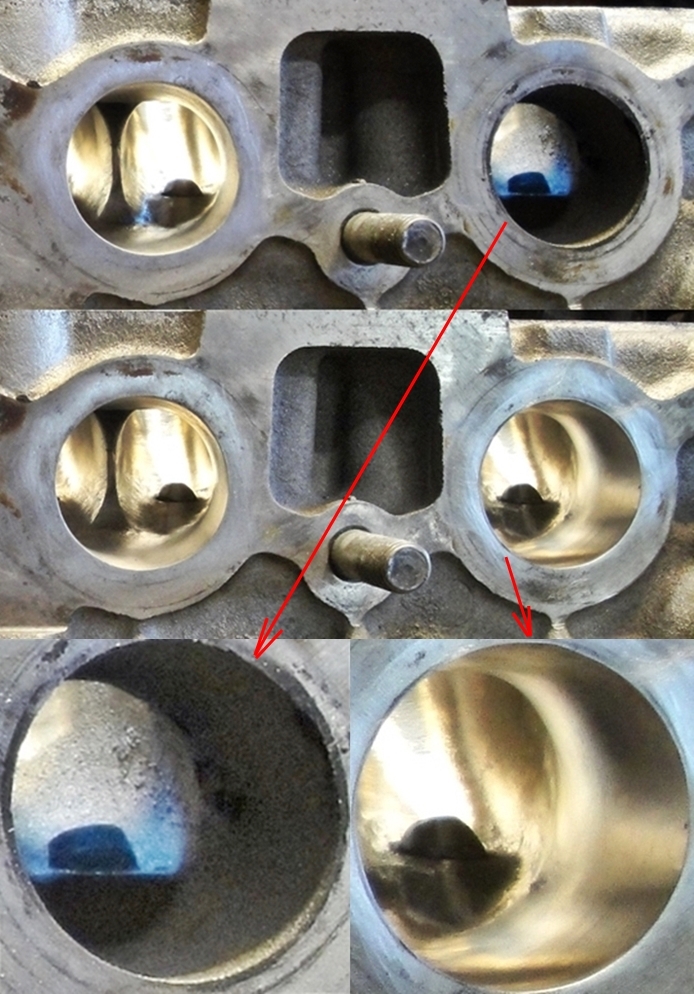

There is one REALLY, and I mean REALLY odd ball bit........ the 3 intake valve seats have NO semblance of an even 3 angle...

Looking into the Blacktop service manual the 3 angles are suppose to be 30, 45, 60. Well the throat cut - 60 degree cut, in essence is the bowl angle and so the back of the port (highest pressure area) has no effective throat cut, while if you look carefully, the throat cut at the short radius is so small, it also becomes more or less insufficient... and the the throat cut between the two... is nothing short of an extreme change - from a width @ the back of the port of almost 5mm, to the width at the short radius of the port of less than 1mm.

I'll been inquiring with a few people as to the best way to address this....

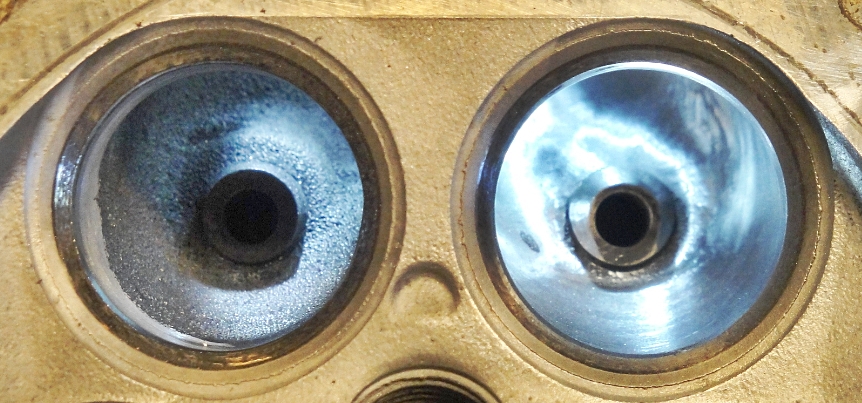

One thing is certain - the factory put a lot more effort in to making the bowls and seats as smooth a transition as the factory could do... the bowl machining marks you see are not by me... those are all factory machining

Adding some more info....

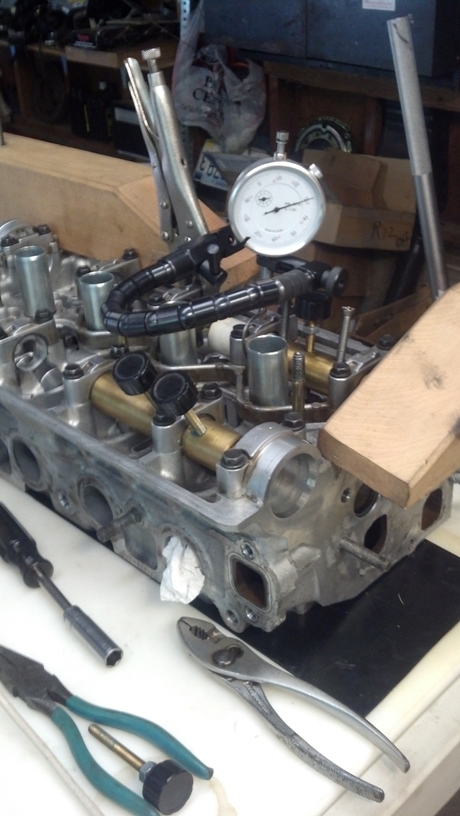

The heads thickness measure.....

My dial caliper is likely off by .001"

and getting a chamber volume

and it is very close to SamQ's 37.8cc measurement.... I'm closer to 38cc

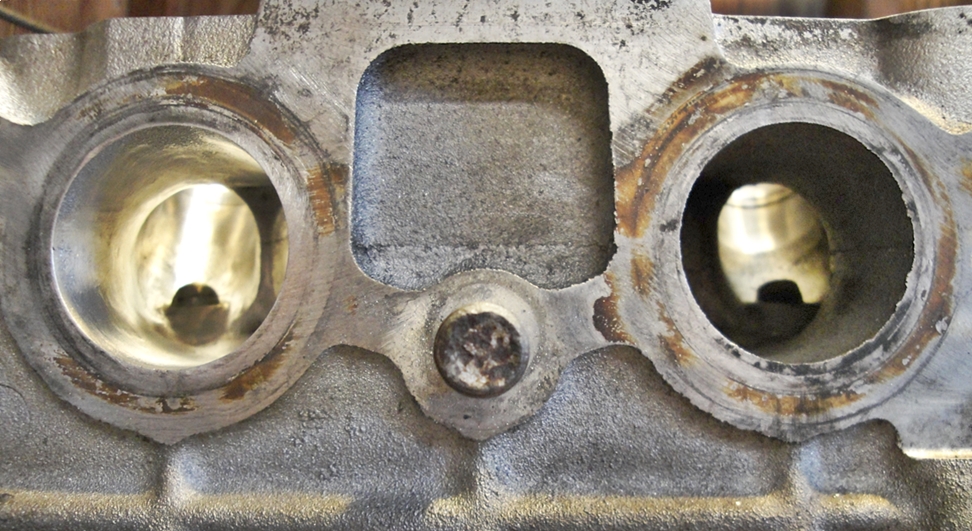

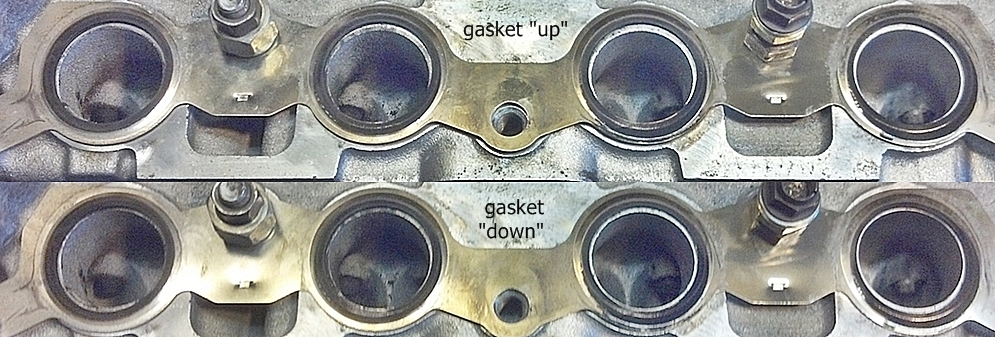

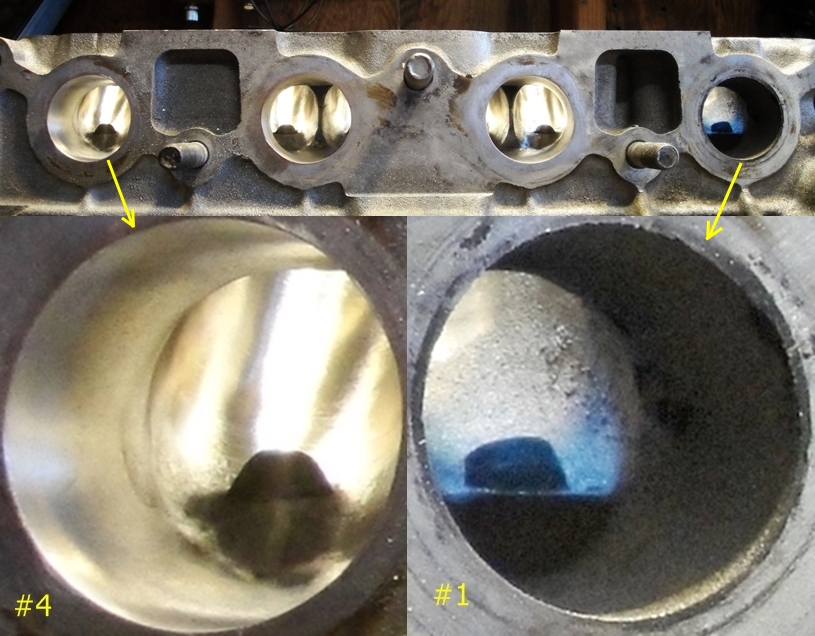

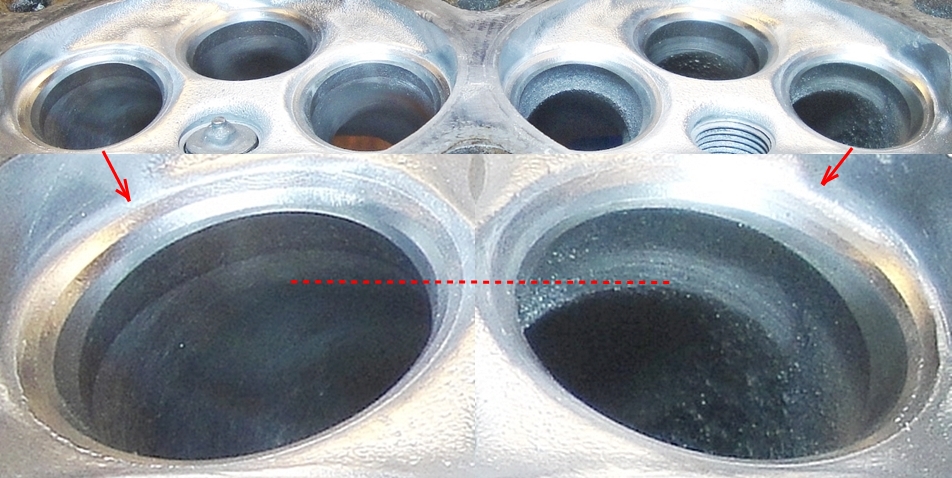

Further inspection......

shows a few issues on the exhaust side... look @ those casting marks.... as they travel from the bowl to the port. Also the small "step" in the machining/casting hurts flow, especially at lower lifts.

More to come........