It is necessary to separate the suspension mechanical links from the spring and

shock. The mechanical links determine the suspension geometry and attach the

wheel assembly to the car. The spring and shock support the weight of the car,

allow the wheel assembly to move as designed, and dampen oscillation.

The orientation and placement of the shock and spring is immaterial. So long

as the required forces can be transferred to the mechanical links, the suspension

will work. Consider the Britten motorcycle where the spring and shock are

located in front of the engine, and the forces are transmitted to the swingarm

by a rocker and tension link.

Manufacturers put the spring and shock in the location that best suits their

packaging and manufacturing goals i.e. where it will fit and at the lowest cost.

The MacPherson strut is a somewhat special case, inasmuch as the strut forms

one of the mechanical links. However, if the strut was changed to a simple

mechanical slider, the spring and shock could both be located elsewhere. But

this would not have met the manufacturers goals.

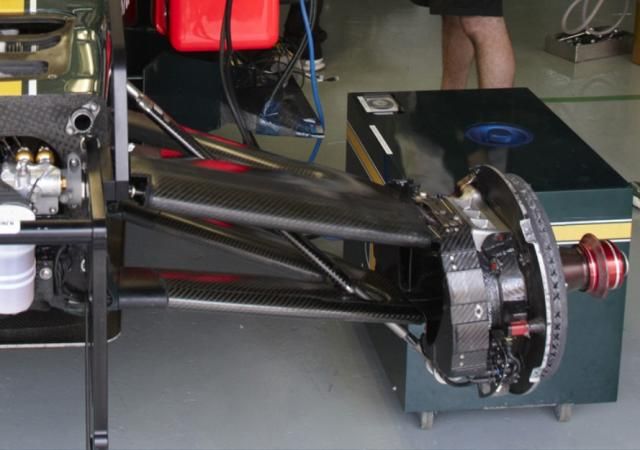

Custom built and performance vehicles are able to be more creative in where

they place their shocks. F1 cars put theirs onboard to reduce drag. Monster

trucks put theirs outboard for cooling and ease of replacement. Installing shocks

on an angle as shown above, means that stiffer shocks and springs are required.

Resolving the forces will show that large part of the spring force acts to try and

push the wheel assemble away from the body of the car.

Supercar makers will use the best performance layout that they can squeeze

into the car regardless of cost. Here is something from a Lambo...

Hope this all helps

Cheers... jondee86