Limited Slip Differentials

Introduction to Limited Slip Differentials (LSD)

The Normal Differential As we well know, a race car driver wins races from shaving lap times by cornering faster. Because of this many teams and constructors try to make cars that maintain higher cornering speeds. On every car a basic differential is fitted to to distribute the engine's power to the driving wheels. The basic differential gear (d1 below) supplies the power to wheels which is/are loaded with least resistance. This allows the cars wheels to run at different speeds in a turn with least resistance. However, when a car is cornering close to it's limit, the car will exhibit roll, a leaning to one side, causing the inside tires to lose forward traction and lateral grip. The wheels lift and cause excessive spin because of lack of downward force or weight distribution. This wheel spin is useless for acceleration until the tires regain traction and start to translate the power to the ground. An LSD is used to alleviate this wheelspin.

Basic Differential Gear system (d1)

The Limited Slip Differential Gear An LSD is constructed similarly to the normal differential. (d2 below)

(A limited slip differential gear figure d2) As you can see, the pressure plate rings have the side gear, pinion, and the pinion gear locked inside, and behind each pressure rings are a number of clutch plates. When torque is applied to the differential, the differential case will spin and throw the pinion into the pressure ring cam. The pressure ring is then pushed out against the clutch plates thereby squeezing them together. This in turn causes the wheels to gradually lock together, depending on the power applied. This effect limits the wheel spin during hard cornering and applies power to the wheels evenly when more power is applied to the wheels. On acceleration and deceleration, it provides even grip and on neutral power, it frees up for less drag and easier turning.

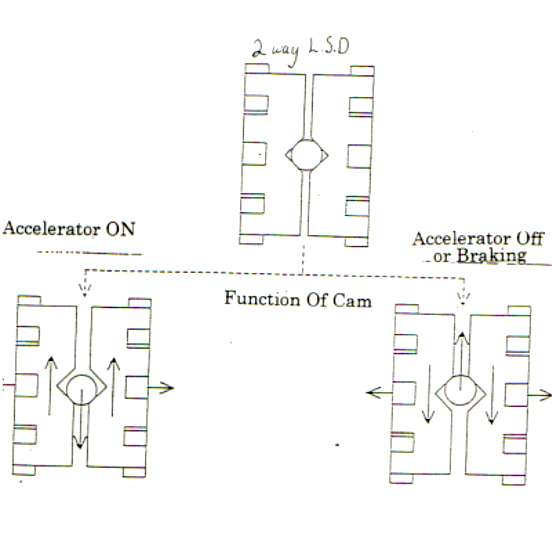

1-Way, 2-Way, 1.5-Way.......... What Does It Mean? Some manufacturers make LSD's in different configurations and are commonly classified as 1 way, 2way, and 1.5 way. This designation reflects the design of the cam groove which enables the LSD to function differently under different loads. A 1 way differential means that the cam is shaped in such way as to have positive lock only when accelerating. The 2 way is constructed in a way to have positive lock motion in either acceleration or deceleration. The 1.5 way is a new term used to describe the 2 way cam which enables different lock up rates during the two directional forces. The 1.5 distribute positive lock stronger under acceleration than when decelerating. The 1.5 way can provide more forgiving balance when braking than a full 2 way setup, although it is less effective for true racing applications, it provides easier operation for beginners in throttle off conditions. It is also effective for front drive cars which need extra stability during braking.

A 2- way limited slip differential - d3

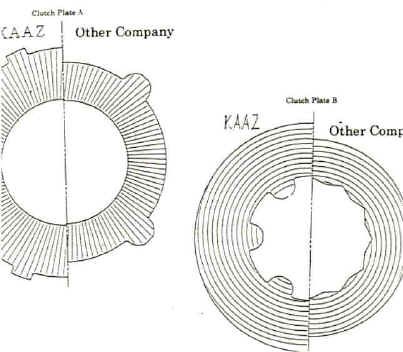

A Comparison of LSD There are many brand and grades of LSD but here's how you rate them. The OEM supplied LSD, standard and optional on many cars today are 2 pinions. This design has very low positive lock and is designed to provide some sporty feel to showroom cars. Because of the nature of this low lock design, it is just slightly more effective than not having one at all. Not a choice for true performance drivers. Barely does doughnuts...! A performance LSD should have at least 4 pinions. This is the design used for racing and rallies around the world. The positive lock ratio and linear lock characteristics is determined by a number of components. The cam profile, clutch plate quantity and size, initial torque of the pre-load spring, as well as the lubricants. Contrary to what manufactures want you to believe, TRD-Toyota Technocraft, Mugen-Honda Racing, RalliArt-Mitsubishi Rally Operations, MazdaSpeed-Mazda, STI-Subaru Technica Int., NISMO- Nissan Motorsports, all have their LSD's made by the same supplier, a Hitachi subsidiary. This is because the majority of the normal differential gears are supplied by them. They use the cheap factory casing and re-work the inside. This limits the size and number of the gears, and clutches thereby sacrificing true potential. They claim 4 pinions but have only 3 or 4 small clutches on one side. They use very high cam profile to put high loads on the clutches so that it can achieve high lock up. The problem with this approach is that the pre-load on the clutches are higher and tires have constant drag. Also, since the clutches are small and few, the load is larger per given surface area, translating into higher operating temperatures and fast wear. Another major disadvantage to this type of LSD has to be the abrupt lock-up, making on-off conditions less predictable and controllable.

The true high-quality Limited Slip are supplied by Kaaz and Cusco, who supply majority of racing teams throughout Japan. The Cusco and Kaaz differentials have on the average 10mm oversize clutch diameter and computer stamped oil channels which hold lubricants during operation. The plates number from 6-8 and have very wide selection of pre-load springs to choose from. Since the clutch has to press together less to achieve very high lock-up, the LSD generates less heat and wears much longer. All components are computer ground and shell casing is not stamped as in the OEM and Branded Hitachi units. Over the long run, these units will cost less to operate due to the lower maintenance required in terms of rebuilding and replacement of clutches. Most of all, these LSDs are much more controllable, having a wider, more progressive lock-up and better positive lock up at the limit. They are more streetable because it won't suddenly spin you around in low traction conditions such as rain and snow. You can, but you can also be in control... To add to this, Kaaz differentials have higher quality tolerance levels, represented by computer balanced shell casing and gears, and initial pre-load springs are matched to vehicle applications. The reason for small application list is that they go through 3 years of N1 and Gr. A racing to design the differential design and specifications. I prefer the KAAZ because of cheaper entry price tag too, made even better by introductory pricing in the US markets. Consider it the ultimate in LSD.